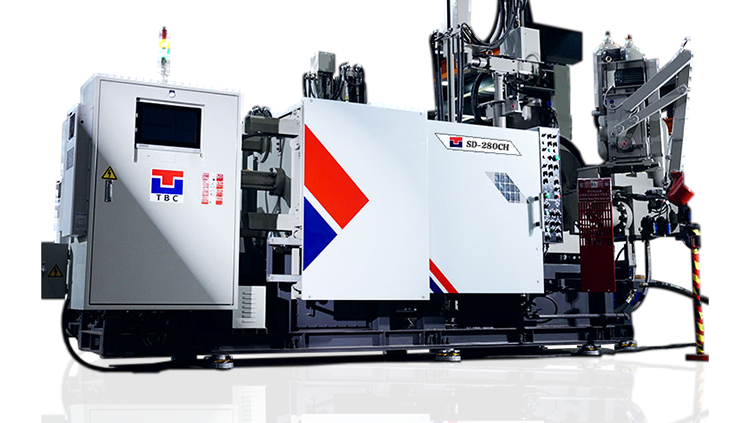

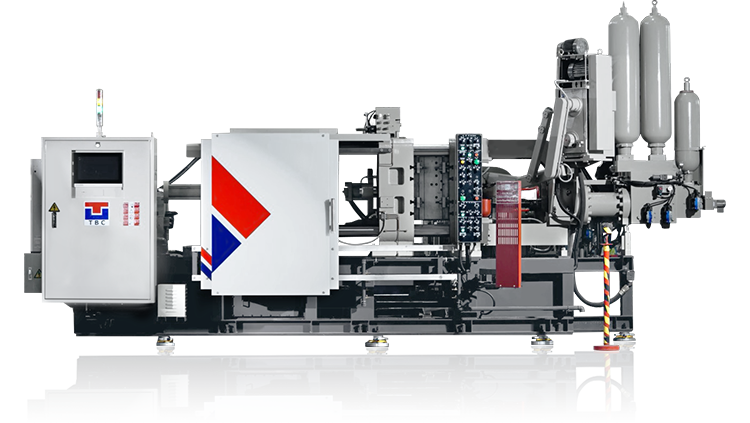

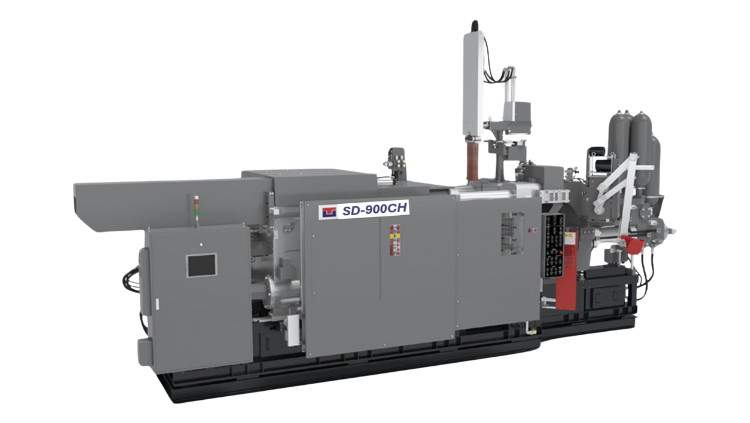

Cold Chamber Aluminum Die Casting Machine - CH Series

High-end INTELLIGENT MODEL

CH series adopts imported energy saving system, and low speed is matched with proportional valve.

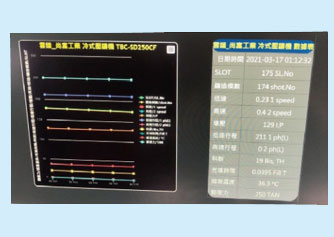

The control accuracy of multi-speed injection is better than the traditional multi-speed injection. Suitable for air-tight castings

- High speed injection 8m/ sec, high speed acceleration 80G.

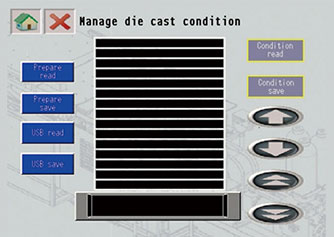

- Complete data management: Standard die clamping force, furnace temperature interface, oil temperature alarm, defective detection and other systems. 500 sets of mold parameters storage.

- With high end auxiliaries: equipped with toggle arm auto ladler and servo sprayer. Highly improving production efficiency and quality.

- Advanced Data Management: Standard for die locking force display.abandoned cast setting.detection of defective. 500 sets of parameter storage.

C Type

Standard Type

Link Type

Advanced Data Management

-

Dual Hydraulic System and Independent Intensification Accumulator:

Owing to the separate ACC for intensification part, the pressure is not influenced by high speed.

Operator can set up IP pressure independently. Suitable for 500 ton machine and above. -

Meter-in Injection System:

New hydrau-lic circuit design is capable to achieve a 80G acceleration and high speed to 8m/s.

With German proportion solenoid valve, precisely controlling multi-phase for low speed and reduce casting porosity.

Higher stability for pressure resistant products and laminar flow die casting.

Meter-in injection system is also standard feature on TBC CH model die-casting machines. With this function, even for difficult molds, the product quality and the machine's production output & performance are is not inferior to that of Toyo die casting machines.

Dual Hydraulic System and Independent Intensification Accumulator

Meter-in Injection System

- Vacuum system interface

- Injection parameters save up to 300 sets.

- Squeeze pin interface

- 15 inch touch screen: Easy for operator to set parameters. The injection data function upgrade.

- Digital Clamping Force Display: Digital clamping force display is standard feature for CH models. Combined with injection data.

- Advanced electronic control function: In addition to defective detection and injection data upgrade. the mold parameter storage is extended to 1,000 sets.

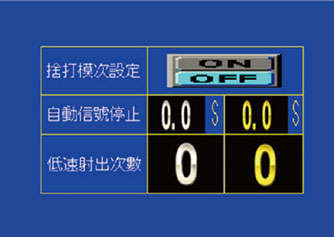

- Abandoned casting setting (warm-up model): Force the machine to operate certain shots under low-speed injection mode, according to shutdown period. Avoiding defective castings due to cold molds.

Digital Clamping Force Display

Advance Electronic Control Function

Abandoned Casting Setting

- Hydraulic oil filter device

- The injection data function upgrade.

-

Remote Data Collection System:

Remoted monitoring and collection of production data.

Simple through mobile phone or laptop. -

Energy Saving System:

With German Eckerle pump and the whole new controlling system. Extend the liftspan and durability.

The power consumption of die casting machines of more than 500 ton is reduced by about 30%. -

Movable Platen Reinforcement Board:

prevents the platen from deforming after long-term use and makes it easy to replace.

-

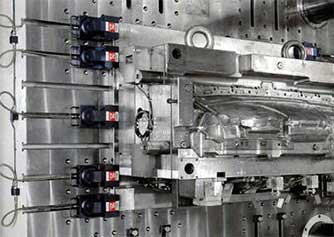

Quick mold Change system:

Using a special hydraulic clamp, the upper and lower molds can be moved quickly and safely. The control and operation can also be integrated into the electronic control of TBC die-casting machine.

-

Automatic safety door:

Using a frequency converter to control the motor system, which is more stable than the traditional air pressure system. The safety door can be automatically opened and closed during production with the machine's movement. It can be installed on both the operating side and the non-operator side.

-

Extra cores:

According to each tonnage model, the number of cores can be additionally increased.

Remote Data Collection System

Energy Saving System

Core

Full Cover Auto Safety Door

Quick Mold Change System

Fixed Platen Side Spray

Piston Type Accumulator

Movable Platen Reinforce Board

Auto Tie Bar Puller on Operator Side (Available for 580T machine and above)

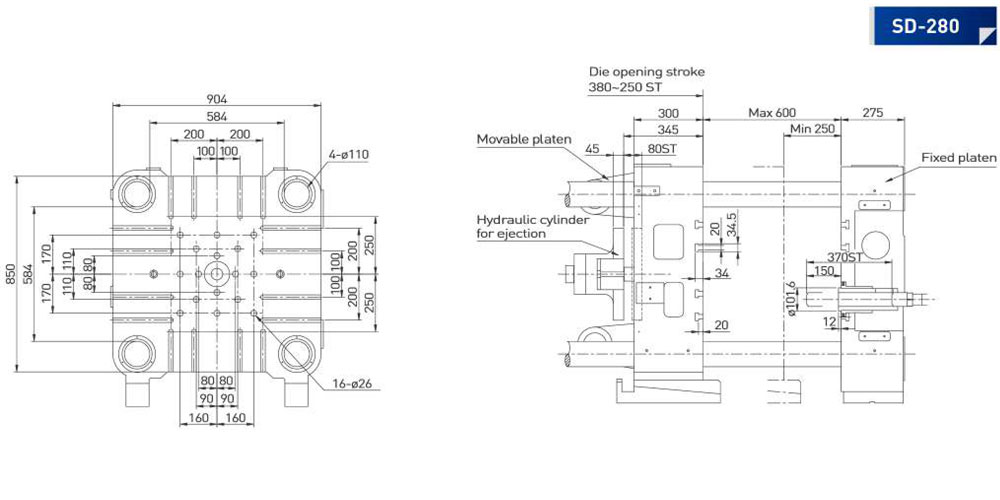

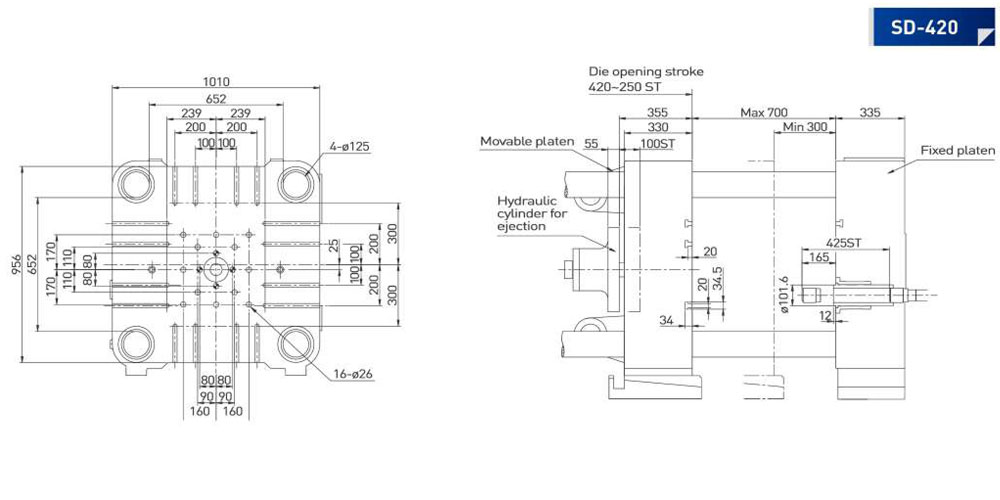

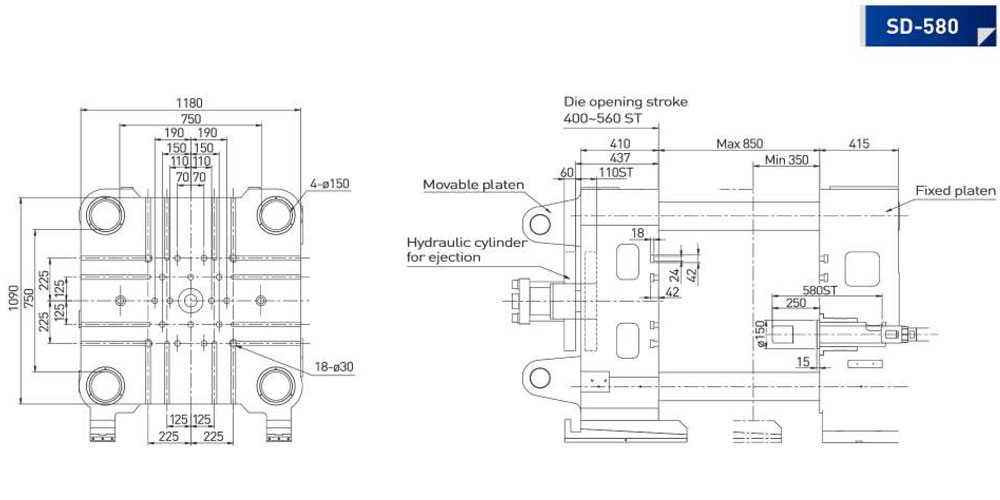

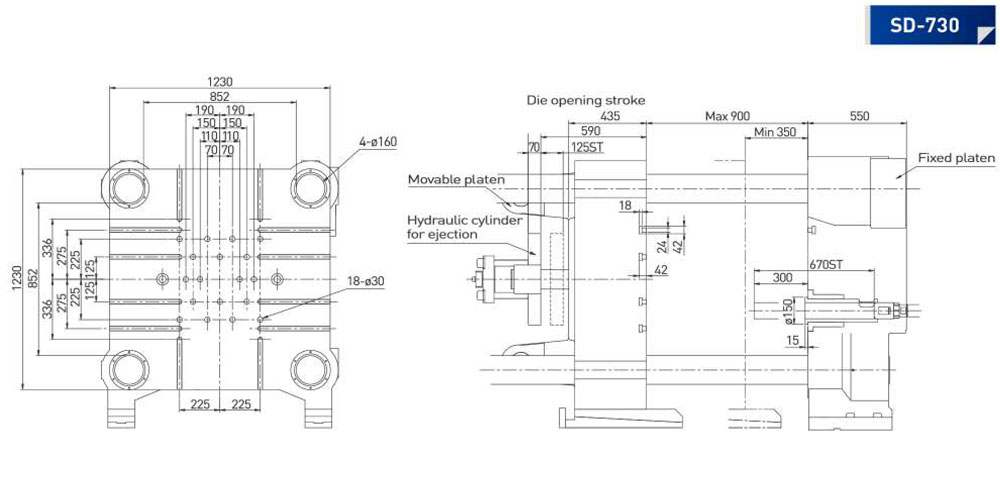

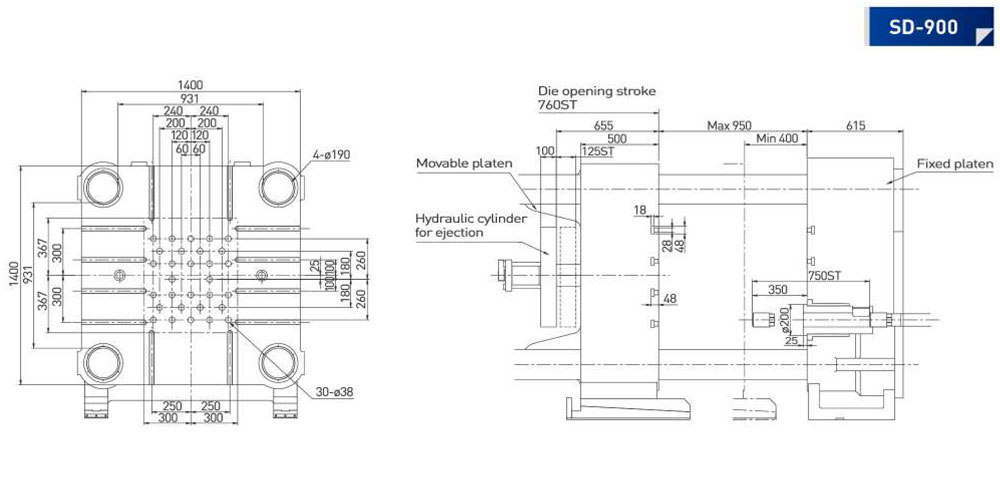

| Item | Units | SD-280 CH | SD-420 CH | SD-580 CH | SD-730 CH | SD-900 CH | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Die locking force | KN | 2800 | 4200 | 5800 | 7300 | 9000 | ||||||||||||||

| Die platen dimensions (HxW) | mm | 850x904 | 1010x1010 | 1090x1180 | 1230x1230 | 1400x1400 | ||||||||||||||

| Space between tie bars | mm | 584x584 | 652x652 | 750x750 | 852x852 | 931x931 | ||||||||||||||

| Tie bar diameter | mm | 110 | 125 | 150 | 160 | 190 | ||||||||||||||

| Die stroke | mm | 380 | 420 | 560 | 660 | 760 | ||||||||||||||

| Die thickness | mm | 250~600 | 300~700 | 350~850 | 350~900 | 400~950 | ||||||||||||||

| Solenoid valve for core | Piece | 3/8"x1 | 3/8"x2 | 3/8"x1 | 3/8"x2 | 1/2"x2 | 1/2"x3 | 1/2"x3 | ||||||||||||

| Hydraulic outlet | Set | 1/2"x2 | 1/2"x3 | 1/2"x2 | 1/2"x3 | 3/4"x3 | 3/4"x5 | 3/4"x5 | ||||||||||||

| Injection force | KN | 265 | 354 | 506 | 550 | 653 | ||||||||||||||

| Plunger stroke | mm | 370 | 425 | 580 | 670 | 750 | ||||||||||||||

| Plunger-tip projection distance | mm | 150 | 165 | 250 | 300 | 350 | ||||||||||||||

| Injection port position | mm | -125 | -150 | -175 | -175 | -250 or -275 | ||||||||||||||

| Dry shot speed | M/S | 6 | 7 | 6 | 7 | 8 | 6 | 7 | 8 | 6 | 7 | 8 | 6 | 7 | 8 | |||||

| Plunger-tip diameter | mm |

Min. 50 |

Sta. 60 |

Max. 70 |

Min. 60 |

Sta. 70 |

Max. 80 |

Min. 70 |

Sta. 80 |

Max. 90 |

Min. 70 |

Sta. 80 |

Max. 90 |

Min. 80 |

Sta. 90 |

Max. 100 |

||||

| Maximun casting pressure | Mpa | 132.8 | 92.3 | 67.7 | 109.9 | 80.6 | 61.7 | 117.7 | 90 | 71.1 | 140.5 | 107.7 | 85.1 | 130 | 102.8 | 83.1 | ||||

| Casting area | cm² |

184 287 |

265 413 |

361 563 |

312 485 |

425 661 |

555 864 |

416 624 |

544 816 |

688 1033 |

462 582 |

604 760 |

764 962 |

653 904 |

826 1144 |

1022 1414 |

||||

| Actual shot weight | Kg | 1.40 | 2.02 | 2.75 | 2.35 | 3.20 | 4.18 | 4.35 | 5.68 | 7.19 | 5 | 6.6 | 8.3 | 7.3 | 9.2 | 11.4 | ||||

| Ejection force | KN | 123.5 | 190.1 | 259.7 | 300 | 340 | ||||||||||||||

| Ejection Stroke | mm | 80 | 100 | 110 | 125 | 125 | ||||||||||||||

| Hydraulic motor | kw | 18.5 | 22.5 | 37 | 37 | 45 | ||||||||||||||

| Amount of hydraulic fluid | L | 370 | 480 | 700 | 800 | 860 | ||||||||||||||

| Amount of cooling water for oil cooling | L/min | 25 | 25 | 80 | 80 | 150 - 180 | ||||||||||||||

| Amount of cooling water for die casting cooling | L/min | 25-50 | 25-50 | 50-90 | 50-90 | 150 | ||||||||||||||

| Machine weight | ton | 9.4 | 12.8 | 23 | 30 | 50 | ||||||||||||||

| Machine size | mm | 5613x1650x2616 | 6275x1835x2975 | 7590x2065x3345 | 8046x2335x3413 | 9990x2450x3556 | ||||||||||||||

| Model | 280 | 420 | 580 | 730 | 900 | |

|---|---|---|---|---|---|---|

| CH | CH | CH | CH | CH | ||

| CONTROLLER PART | ||||||

| Color touch screen |

|

|

|

|

|

|

| Alarm display |

|

|

|

|

|

|

| Injection terms setting |

|

|

|

|

|

|

| Screen print |

|

|

|

|

|

|

| PLATEN PART | ||||||

| Cycle time setting |

|

|

|

|

|

|

| Die open lubricating setting |

|

|

|

|

|

|

| Ejection stroke setting from screen |

|

|

|

|

|

|

| Movable platen adjustment |

|

|

|

|

|

|

| Toggles auto lubricating system |

|

|

|

|

|

|

| Auto tie bar puller |

|

|

|

|

|

|

| CORE PART | ||||||

| Selection of core movement timer |

|

|

|

|

|

|

| Selection of core pressure during injection |

|

|

|

|

|

|

| Movable core 1 |

|

|

|

|

|

|

| Movable core 2 |

|

|

|

|

|

|

| Fixed core 3 |

|

|

|

|

|

|

| Pressure reducing valve for movable core 1&2 |

|

|

|

|

|

|

| Pressure reducing valve for fixed core 3 |

|

|

|

|

|

|

| INJECTION PART | ||||||

| Motorized injection valve |

|

|

|

|

|

|

| Injection curve display |

|

|

|

|

|

|

| Die cast conditions management |

|

|

|

|

|

|

| Injection speed display |

|

|

|

|

|

|

| Injection pressure display |

|

|

|

|

|

|

| Injection data display |

|

|

|

|

|

|

| Plunger-tip projection setting |

|

|

|

|

|

|

| Injection vacuum movement setting |

|

|

|

|

|

|

| Shot sleeve clean setting |

|

|

|

|

|

|

| Plunger-tip lubricating setting |

|

|

|

|

|

|

| Injection stroke setting from screen |

|

|

|

|

|

|

| Magnetic non-contact sensor |

|

|

|

|

|

|

| Intensifying pressure adjustment |

|

|

|

|

|

|

| HYDRAULIC & COOLING PART | ||||||

| Hydraulic oil temperature sensor |

|

|

|

|

|

|

| Hydraulic oil level sensor |

|

|

|

|

|

|

| Enhanced cooler |

|

|

||||

| Auto pressure release device |

|

|

|

|

|

|

| Hydraulic oil filter device |

|

|

|

|

|

|

| SAFETY PART | ||||||

| Manual safety door |

|

|

|

|

|

|

| Full cover auto safety door |

|

|

|

|

|

|

| Non-operator side safety fence (without auto extractor) |

|

|

|

|

|

|

| Emegency stop |

|

|

|

|

|

|

| OTHERS | ||||||

| Energy saving system |

|

|

|

|

|

|

| Digital die locking force display |

|

|

|

|

|

|

| Quick mould change system |

|

|

|

|

|

|

| Squeeze pin interface |

|

|

|

|

|

|

| Piston accumulator |

|

|

|

|

|

|

| Movable platen reinforce board |

|

|

|

|

|

|

| AUXILIARIES | ||||||

| Auto ladler: Molten metal volume calculating |

|

|

|

|

|

|

|

Auto adjustment for molten metal supply standby timer |

|

|

|

|

|

|

| Ladle descending position setting |

|

|

|

|

|

|

| Molten metal volume from screen |

|

|

|

|

|

|

| Auto extractor die height auto adjust |

|

|

|

|

|

|

| Auto sprayer die height auto adjust |

|

|

|

|

|

|

| Auto sprayer: Up down movement spray |

|

|

|

|

|

|

| Spray setting for male, female mold |

|

|

|

|

|

|

| Spray setting for cores |

|

|

|

|

|

|

| Fast auto production |

|

|

|

|

|

|

Standard Standard  Option Option  Not Available Not Available

|

||||||