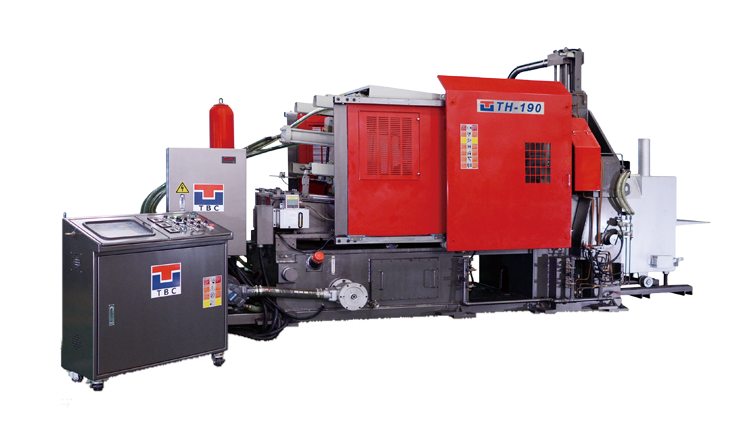

Hot Chamber Die Casting Machine

Rigid & durable. Steady mechanism design. User friendly interface.

We have 30 years of R&D experience in cold-chamber die-casting machine industry best for us to produce easy-to-use, robust and stable hot-chamber die-casting machines.

High-performance Hot Chamber Die Casting Machines for Aluminum, Magnesium, Zinc, and Other Alloys

TBC is a hot chamber die casting machine manufacturer with more than 20 years of experience in Taiwan. This hot chamber die casting machine is suitable for aluminum, magnesium, zinc and other alloy metals, and is mainly supplied to the United States, India, Vietnam, Indonesia, Malaysia, Middle East, Eastern Europe, Africa.

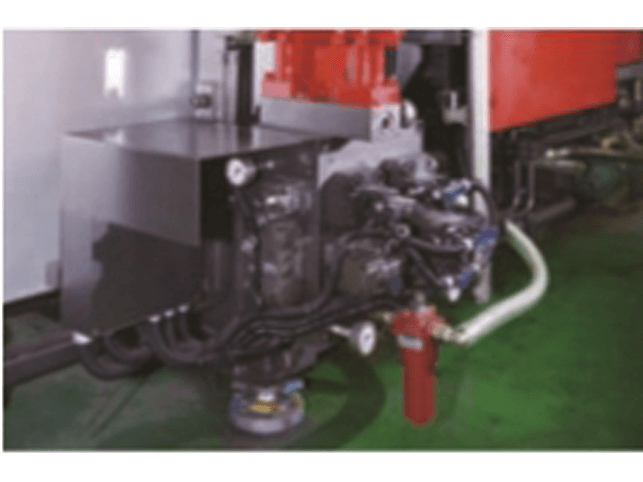

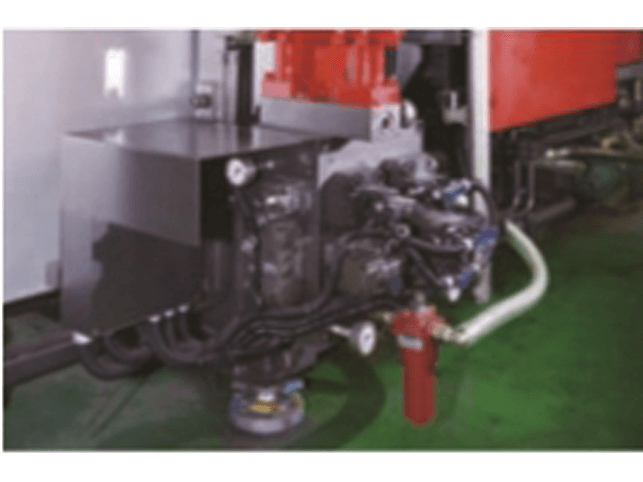

- Controlled by Proportional solenoid valve

- -Excellent in injection intensity

- -Precisely control to enhance component quality

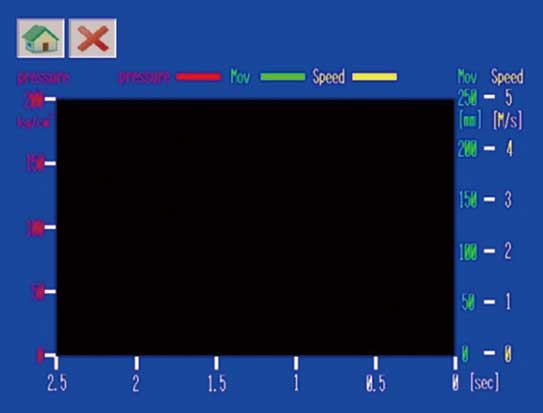

- Three-phase injection mechanism

- -Provide low speed, high speed, and pressure retention

- -Enhance air-tightness in pressure retention period

Controlled By Proportional Solenoid Valve

Three-phase Injection Mechanism

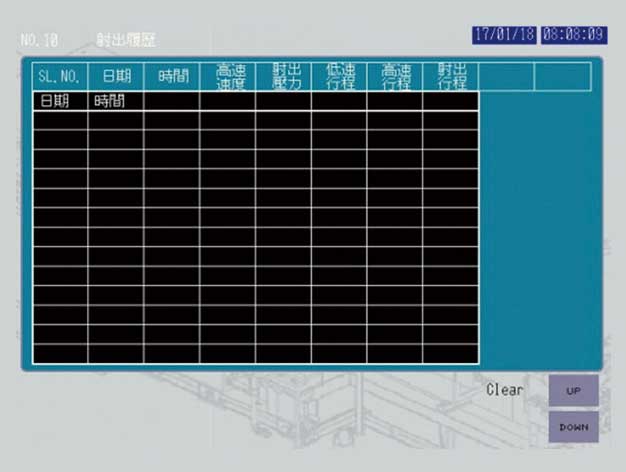

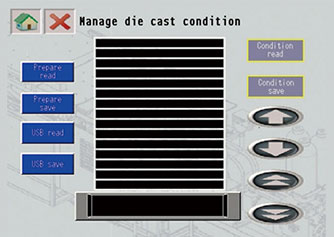

- Data Management

- -Up to 250 sets of casting conditions able to be stored

- -Enhance management efficiency

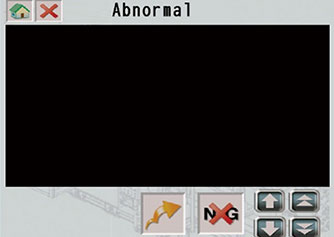

- Error message display

- -Abnormal message for troubleshooting

- Three curves displayed in the figure: Pressure, Distance and Time

- Injection data will be displayed on the screen for further usage

- Proportional Solenoid Valve

- -Smooth die close/open

- -Short die close/open cycle

- Adjustable Sliding Shoes

- -Adjustable platen height

- -Keep movable platen in center position

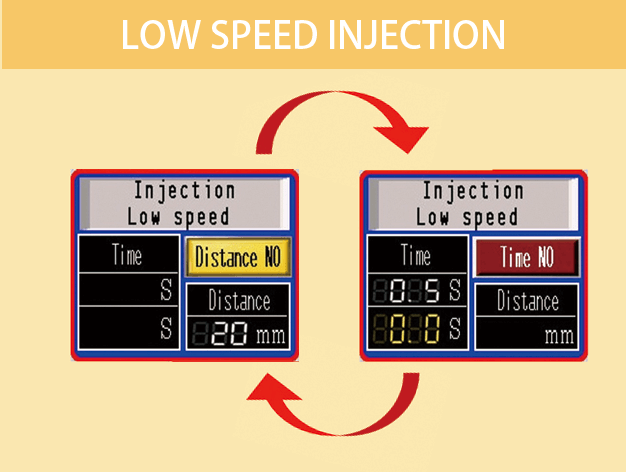

- Freely switch between time/distance in low speed injection modes

- Effectively control the pressure and speed of injection with measured values provided

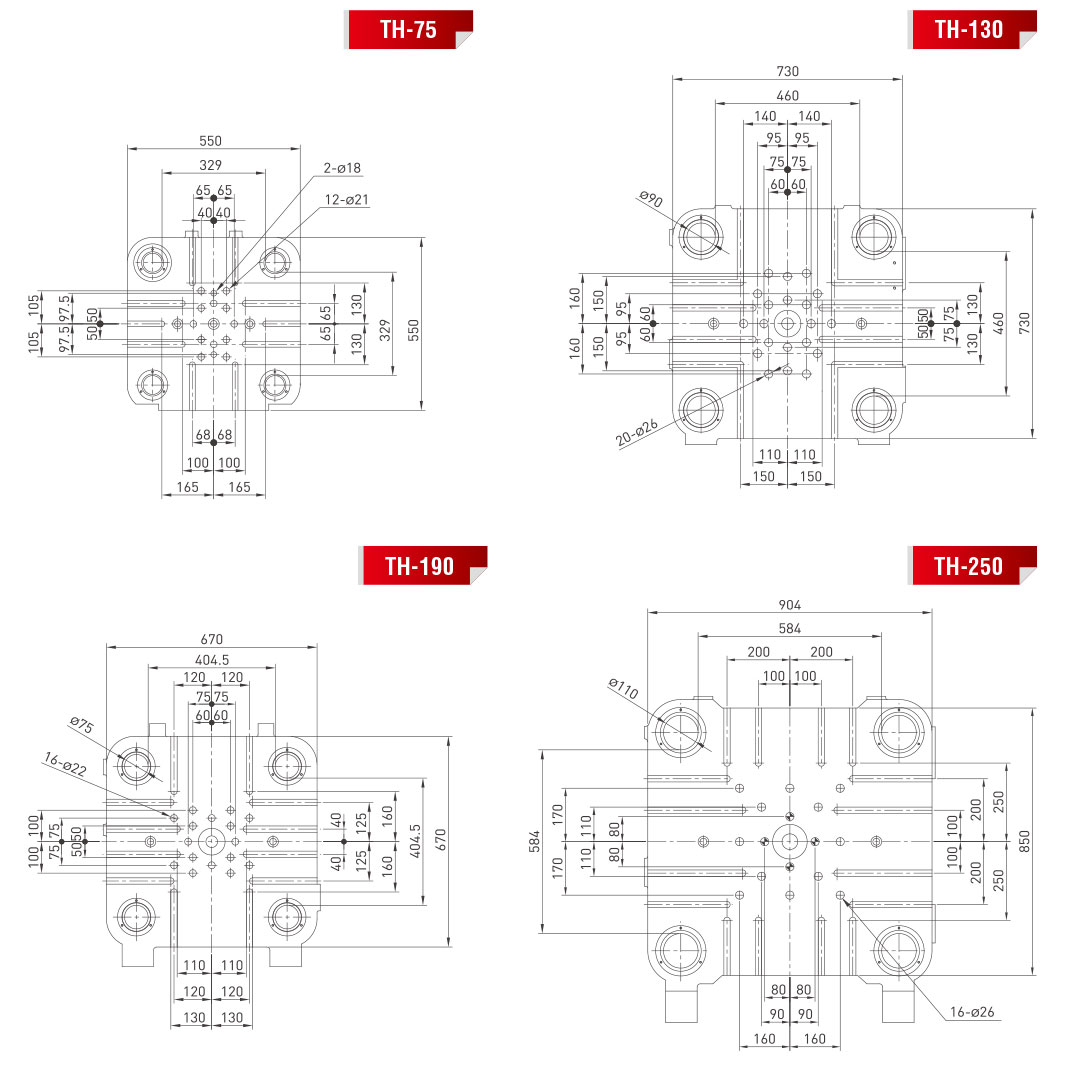

| Model | Units | TH-75 | TH-130 | TH-190 | TH-250 |

|---|---|---|---|---|---|

| Planten Part | |||||

| Die clamping force | ton | 75 | 130 | 190 | 250 |

| Tie bar diameter | mm | 60 | 75 | 90 | 110 |

| Die platen dimensions (HxV) | mm | 550 x 550 | 640 x 640 | 730 x 730 | 850 x 904 |

| Space between tie bars | mm | 329 x329 | 400 x 400 | 460 x 460 | 584 x 584 |

| Die stroke | mm | 210 | 310 | 350 | 380 |

| Die thickness | mm | 120~400 | 140~480 | 150~500 | 200~600 |

| Nozzle matching force | mm | 5.1 | 6.0 | 7.5 | 13.0 |

| Nozzle stroke | mm | 200 | 200 | 200 | 250 |

| Injection part | |||||

| Injection cylinder diameter | mm | 80 | 100 | 120 | 120 |

| Maximum injection force | ton | 5 | 7.85 | 10 | 12.5 |

| Maximum injection stroke | mm | 125 | 190 | 190 | 200 |

| Injector rod diameter (standard) | mm | 50 | 60 | 65 | 75 |

| Actual shot weight (zinc) | g | 1200 | 2500 | 3000 | 4500 |

| Furnace capacity (zinc) | mm | 0 , 60 | 0 , 80 | 0 , -100 | 0 , -150 |

| Maximum casting area | cm² | 253 | 494 | 615 | 929 |

| Casting pressure | kg/cm² | 256 | 200 | 238 | 269 |

| Ejection part | |||||

| Ejection force | ton | 5 | 6 | 7.5 | 10.5 |

| Ejection stroke | mm | 70 | 70 | 80 | 100 |

| Hydraulic part | |||||

| Operating pressure | kg/cm² | 110 | 110 | 110 | 125 |

| Accumulator (hydac) N2 (injection) | l/ea | 20 x 1 | 20 x 2 | 20 x 2 | 32 x 2 |

| Accumulator (hydac) N2 (die close) | l/ea | 10 x 1 | 20 x 1 | 32 x 1 | 50 x 2 |

| Oli tank capacity | l | 200 | 400 | 600 | 800 |

| Electrical part | |||||

| Electrical motor | kw | 11.0 | 15.0 | 18.5 | 30.0 |

| Machine size | |||||

| Machine weiht | ton | 5 | 7.5 | 10.5 | 14.7 |

| Machine size | m | 4.2x2.0x1.8 | 4.3x2.2x2.3 | 4.8x2.1x2.5 | 5.5x2.2x2.6 |