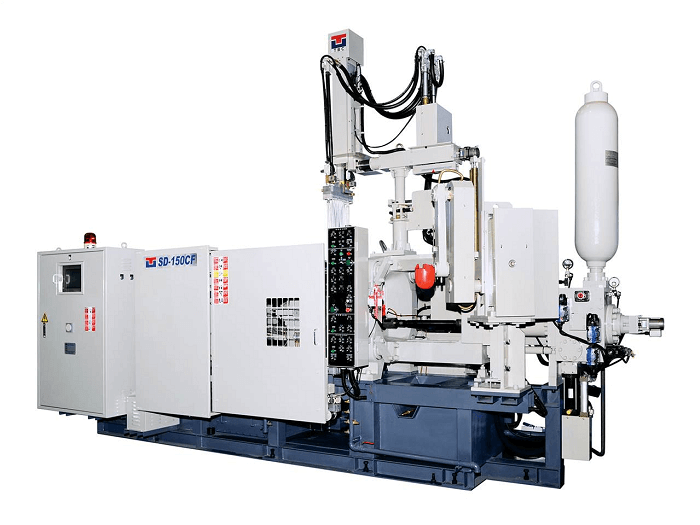

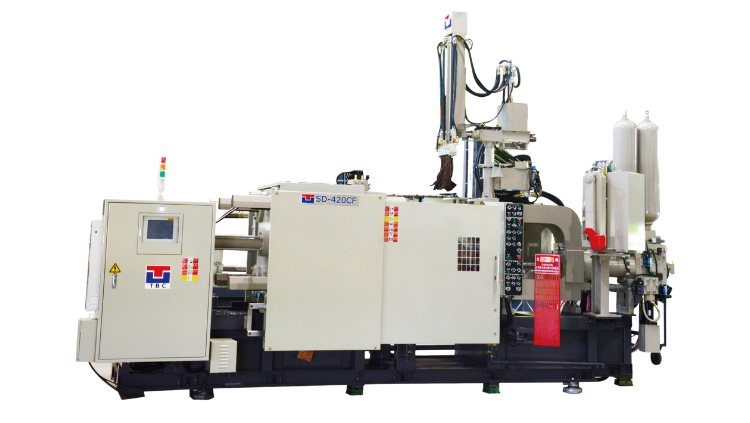

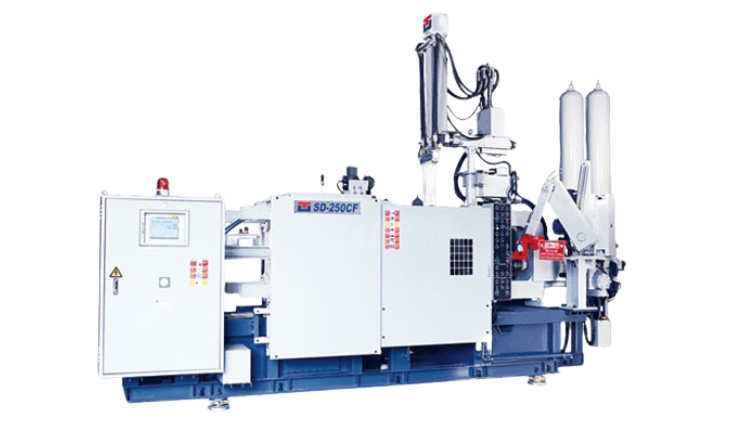

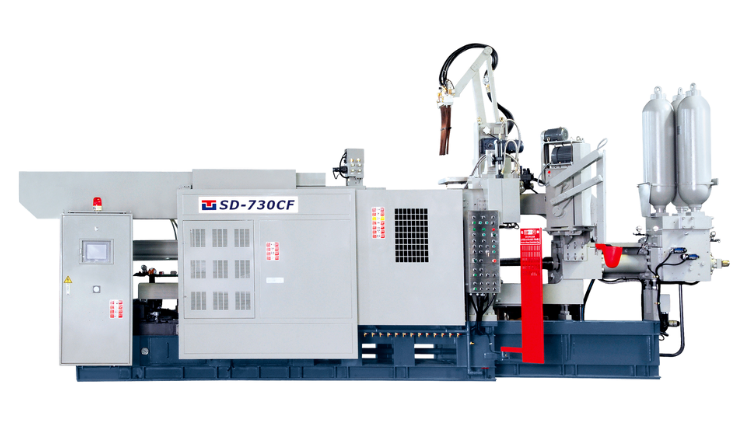

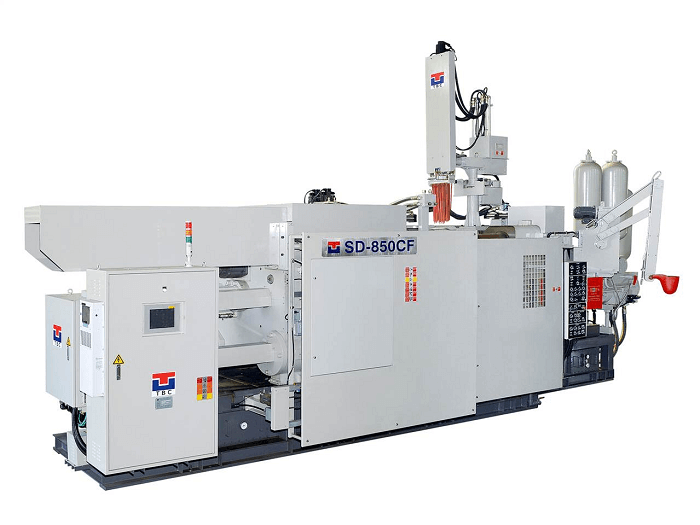

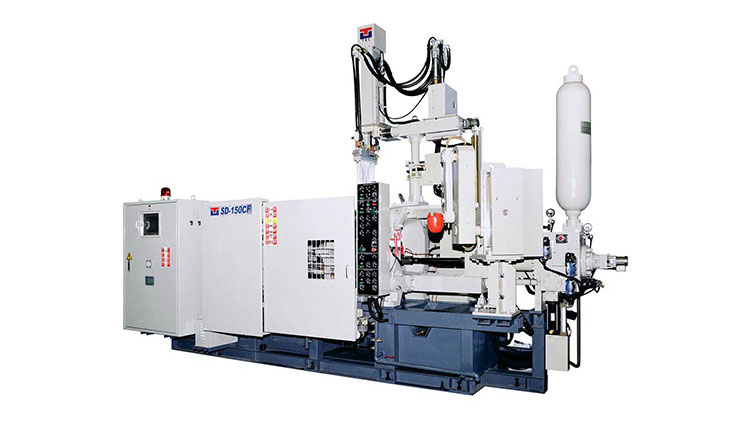

Cold Chamber Aluminum Die Casting Machine - CF Series

Advanced Cold Chamber Die Casting Machine Manufacturers in Taiwan

Powerful performance for high productivity. Fast cycle time, efficient & stable. More facilities & higher controllability. Complete management assistance. Easy to use. We provide high quality cold chamber die casting machine to United States, India, Pakistan, the Middle East and China at an affordable price.

Providing Cold Chamber Die Casting Machine at an affordable price

TBC is famous for its die cast automation production in the die-casting machine industry. With years of rich manufacturing experience, fully researching and developing all kinds of high-performance automatic die-casting technology. We are convinced that TBC will be your best choice for die cast automation equipment worldwide. TBC is committed to producing cold chamber die casting equipment with excellent quality and affordable price

In addition to CE series, some other functions are enhanced as following:

- Injection valve is controlled electronically. Injection pressure can be detected. Digitized injection stroke, simple design, stable casting.

- Dry shot speed: 7 m/sec

- Cycle time can be set and monitored.

- Dual ACC and Circult Design( for 250 ton and above ): Efficiently reducing the pressure drop and providing superior reaction of refilling pressure. More stable in injection.

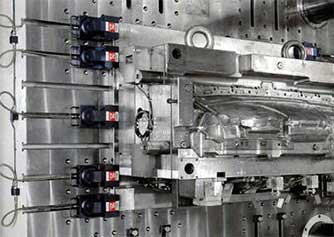

- Core movements is controlled by Limit Switch / Timer.

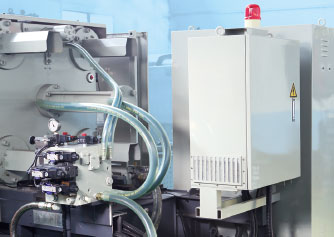

- Back Pressure Relief Device: With unique hydraulic circuit design. acceleration from low to high speed taking only 0.012 seconds.

- Data Storage: 3000 sets of injection data, 300 sets of casting parameters and die cast conditions all stored effectively in USB flash drive for future reference and comparison.

- Optional for Servo Sprayer: Adjustable for spraying stroke. Providing better quality and atomization effect.

Back Pressure Relief Device

CF Injection Block Feature

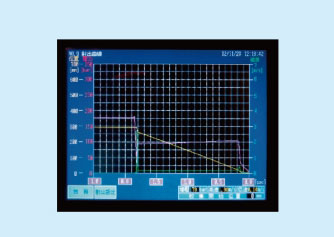

Data Storage

- Vacuum system interface

- Digital die locking force display

- Injection parameters save up to 300 sets.

- Squeeze pin interface

- Hydraulic oil filter device

- Multi-speed Injection System: Having 5 low speed setting Elimi-nating air entrainment and molten metal flash. Effectively enhancing quality and able to lower porosity.

Core

Hydraulic Oil Level Sensor

Full Cover Auto Safety Door

Quick Mold Change System

Energy Saving System

Fixed Platen Side Spray

Movable Platen Reinforce Board

Auto Tie Bar Puller on Operator Side (Available for 580T machine and above)

| Item | Units | SD-150 CF | SD-180 CF | SD-280 CF | SD-420 CF | SD-580 CF | SD-730 CF | SD-900 CF | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Die locking force | KN | 1500 | 1800 | 2800 | 4200 | 5800 | 7300 | 9000 | |||||||||||||||

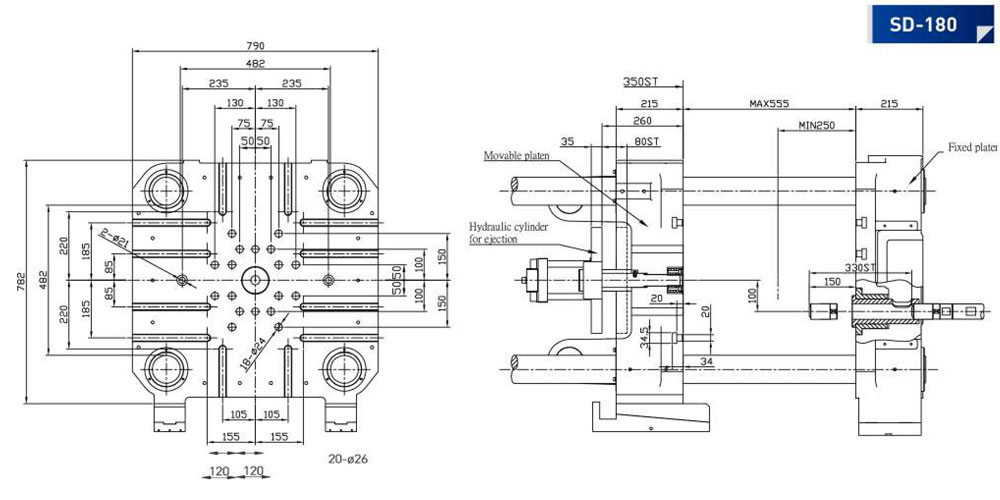

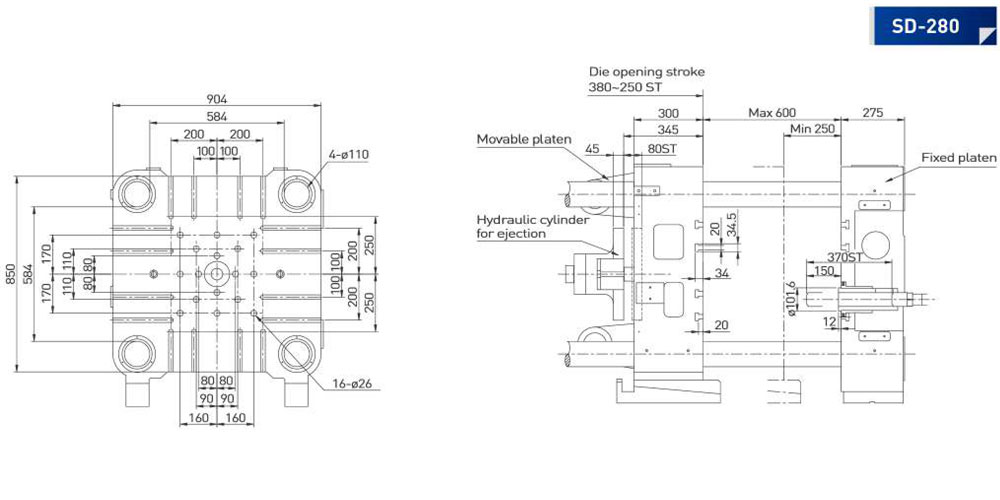

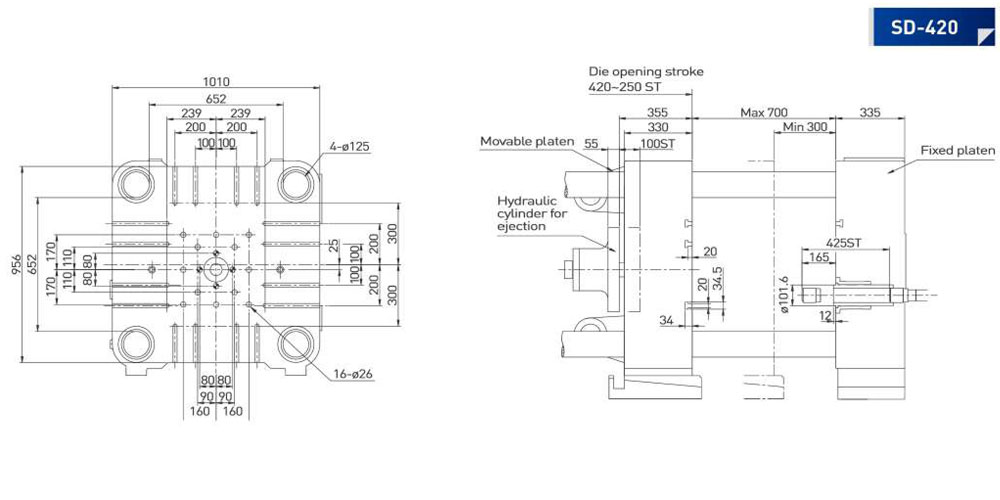

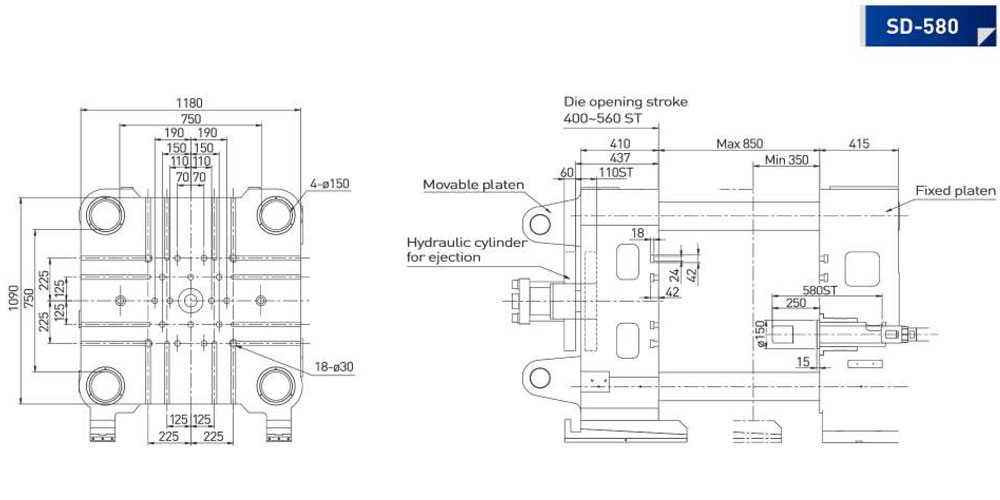

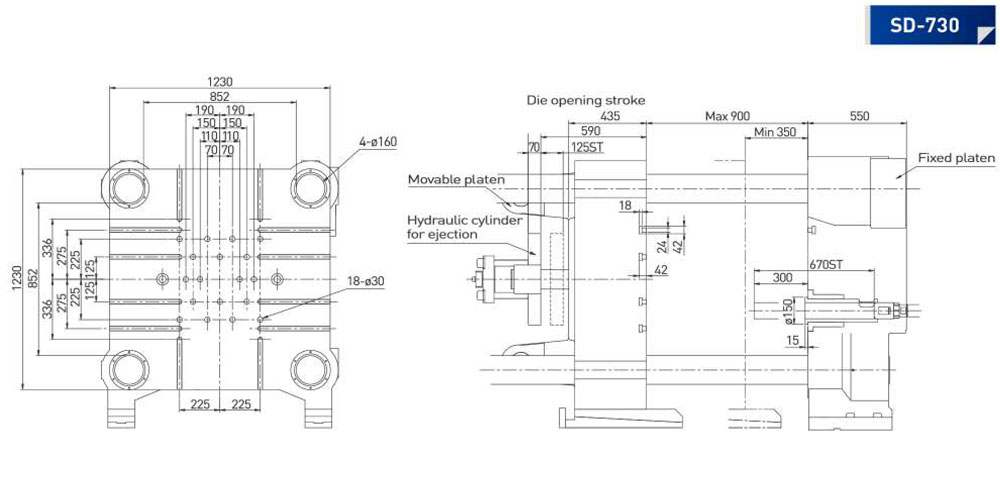

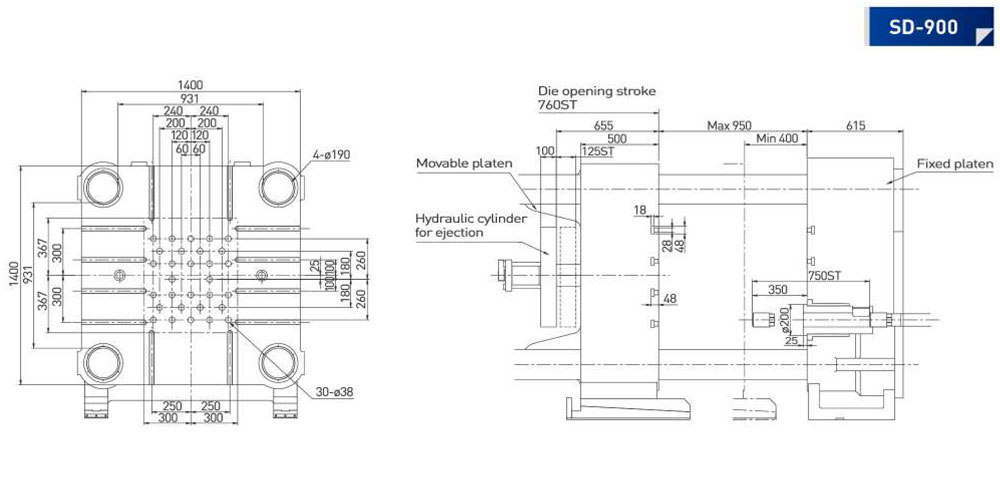

| Die platen dimensions (HxW) | mm | 730x730 | 790x790 | 850x904 | 1010x1010 | 1090x1180 | 1230x1230 | 1400x1400 | |||||||||||||||

| Space between tie bars | mm | 460x460 | 482x482 | 584x584 | 652x652 | 750x750 | 852x852 | 931x931 | |||||||||||||||

| Tie bar diameter | mm | 90 | 110 | 125 | 150 | 160 | 190 | ||||||||||||||||

| Die stroke | mm | 350 | 380 | 420 | 560 | 660 | 760 | ||||||||||||||||

| Die thickness | mm | 250~500 | 250~600 | 300~700 | 350~850 | 350~900 | 400~950 | ||||||||||||||||

| Solenoid valve for core | Piece | 3/8"x1 | 3/8"x2 | 3/8"x1 | 3/8"x2 | 3/8"x1 | 3/8"x2 | 1/2"x2 | 1/2"x3 | 1/2"x3 | |||||||||||||

| Hydraulic outlet | Set | 1/2"x2 | 1/2"x2 | 1/2"x2 | 1/2"x3 | 1/2"x2 | 1/2"x3 | 3/4"x3 | 3/4"x5 | 3/4"x5 | |||||||||||||

| Injection force | KN | 182 | 265 | 354 | 506 | 550 | 653 | ||||||||||||||||

| Plunger stroke | mm | 330 | 370 | 425 | 580 | 670 | 750 | ||||||||||||||||

| Plunger-tip projection distance | mm | 150 | 150 | 165 | 250 | 300 | 350 | ||||||||||||||||

| Injection port position | mm | -100 | -125 | -150 | -175 | -175 | -250 or -275 | ||||||||||||||||

| Dry shot speed | M/S | 6 | 7 | 6 | 7 | 8 | 6 | 7 | 8 | 6 | 7 | 8 | 6 | 7 | 8 | 7 | 8 | ||||||

| Plunger-tip diameter | mm |

Min. 45 |

Sta. 50 |

Max. 60 |

Min. 50 |

Sta. 60 |

Max. 70 |

Min. 60 |

Sta. 70 |

Max. 80 |

Min. 70 |

Sta. 80 |

Max. 90 |

Min. 70 |

Sta. 80 |

Max. 90 |

Min. 80 |

Sta. 90 |

Max. 100 |

||||

| Maximun casting pressure | Mpa | 110.2 | 88.9 | 61.7 | 132.8 | 92.3 | 67.7 | 109.9 | 80.6 | 61.7 | 117.7 | 90 | 71.7 | 140.5 | 107.7 | 85.1 | 130 | 102.8 | 83.1 | ||||

| Casting area | cm² |

133 207 |

165 257 |

238 370 |

184 287 |

265 413 |

361 563 |

312 485 |

425 661 |

555 864 |

416 624 |

544 816 |

688 1033 |

462 582 |

604 760 |

764 962 |

653 904 |

826 1144 |

1022 1414 |

||||

| Actual shot weight | Kg | 0.92 | 1.16 | 1.67 | 1.40 | 2.02 | 2.75 | 2.35 | 3.20 | 4.18 | 4.35 | 5.68 | 7.19 | 5 | 6.6 | 8.3 | 7.3 | 9.2 | 11.4 | ||||

| Ejection force | KN | 100.9 | 123.5 | 190.1 | 259.7 | 300 | 340 | ||||||||||||||||

| Ejection Stroke | mm | 80 | 80 | 100 | 110 | 125 | 125 | ||||||||||||||||

| Hydraulic motor | kw | 15 | 18.5 | 22.5 | 37 | 37 | 45 | ||||||||||||||||

| Amount of hydraulic fluid | L | 360 | 370 | 480 | 700 | 800 | 860 | ||||||||||||||||

| Amount of cooling water for oil cooling | L/min | 25 | 25 | 25 | 80 | 80 | 150 - 180 | ||||||||||||||||

| Amount of cooling water for die casting cooling | L/min | 25-50 | 25-50 | 25-50 | 50-90 | 50-90 | 150 | ||||||||||||||||

| Machine weight | ton | 5 | 9.4 | 12.8 | 23 | 30 | 50 | ||||||||||||||||

| Machine size | mm | 4820x1520x2585 | 5613x1650x2616 | 6275x1835x2975 | 7590x2065x3345 | 8046x2335x3413 | 9990x2450x3556 | ||||||||||||||||

| Model | 150 | 180 | 280 | 420 | 580 | 730 | 900 |

|---|---|---|---|---|---|---|---|

| CF | CF | CF | CF | CF | |||

| CONTROLLER PART | |||||||

| Color touch screen |

|

|

|

|

|

|

|

| Alarm display |

|

|

|

|

|

|

|

| Injection terms setting |

|

|

|

|

|

|

|

| Screen print |

|

|

|

|

|

|

|

| PLATEN PART | |||||||

| Cycle time setting |

|

|

|

|

|

|

|

| Die open lubricating setting |

|

|

|

|

|

|

|

| Ejection stroke setting from screen |

|

|

|

|

|

|

|

| Movable platen adjustment |

|

|

|

|

|

|

|

| Toggles auto lubricating system |

|

|

|

|

|

|

|

| Auto tie bar puller |

|

|

|

|

|

|

|

| CORE PART | |||||||

| Selection of core movement timer |

|

|

|

|

|

|

|

| Selection of core pressure during injection |

|

|

|

|

|

|

|

| Movable core 1 |

|

|

|

|

|

|

|

| Movable core 2 |

|

|

|

|

|

|

|

| Fixed core 3 |

|

|

|

|

|

|

|

| Pressure reducing valve for movable core 1&2 |

|

|

|

|

|

|

|

| Pressure reducing valve for fixed core 3 |

|

|

|

|

|

|

|

| INJECTION PART | |||||||

| Motorized injection valve |

|

|

|

|

|

|

|

| Injection curve display |

|

|

|

|

|

|

|

| Die cast conditions management |

|

|

|

|

|

|

|

| Injection speed display |

|

|

|

|

|

|

|

| Injection pressure display |

|

|

|

|

|

|

|

| Injection data display |

|

|

|

|

|

|

|

| Plunger-tip projection setting |

|

|

|

|

|

|

|

| Injection vacuum movement setting |

|

|

|

|

|

|

|

| Shot sleeve clean setting |

|

|

|

|

|

|

|

| Plunger-tip lubricating setting |

|

|

|

|

|

|

|

| Injection stroke setting from screen |

|

|

|

|

|

|

|

| Magnetic non-contact sensor |

|

|

|

|

|

|

|

| Intensifying pressure adjustment |

|

|

|

|

|

|

|

| HYDRAULIC & COOLING PART | |||||||

| Hydraulic oil temperature sensor |

|

|

|

|

|

|

|

| Hydraulic oil level sensor |

|

|

|

|

|

|

|

| Enhanced cooler |

|

|

|

|

|||

| Auto pressure release device |

|

|

|

|

|

|

|

| Hydraulic oil filter device |

|

|

|

|

|

|

|

| SAFETY PART | |||||||

| Manual safety door |

|

|

|

|

|

|

|

| Full cover auto safety door |

|

|

|

|

|

|

|

| Non-operator side safety fence (without auto extractor) |

|

|

|

|

|

|

|

| Emegency stop |

|

|

|

|

|

|

|

| OTHERS | |||||||

| Energy saving system |

|

|

|

|

|

|

|

| Digital die locking force display |

|

|

|

|

|

|

|

| Quick mould change system |

|

|

|

|

|

|

|

| Squeeze pin interface |

|

|

|

|

|

|

|

| Piston accumulator |

|

|

|

|

|

|

|

| Movable platen reinforce board |

|

|

|

|

|

|

|

| AUXILIARIES | |||||||

| Auto ladler: Molten metal volume calculating |

|

|

|

|

|

|

|

|

Auto adjustment for molten metal supply standby timer |

|

|

|

|

|

|

|

| Ladle descending position setting |

|

|

|

|

|

|

|

| Molten metal volume from screen |

|

|

|

|

|

|

|

| Auto extractor die height auto adjust |

|

|

|

|

|

|

|

| Auto sprayer die height auto adjust |

|

|

|

|

|

|

|

| Auto sprayer: Up down movement spray |

|

|

|

|

|

|

|

| Spray setting for male, female mold |

|

|

|

|

|

|

|

| Spray setting for cores |

|

|

|

|

|

|

|

| Fast auto production |

|

|

|

|

|

|

|

Standard Standard  Option Option  Not Available Not Available

|

|||||||

- Smart QC System: Equipped with injection data display. injection diagram, defective detection. Oil temperature sensor, oil level sensor (optional), die locking force display (optional).

- Assist Production System: Standard for abandoned cast setting. display of injection valve and pressure. timer setting of core position, and shot condition calculation.

Smart QC System

Assist Production System