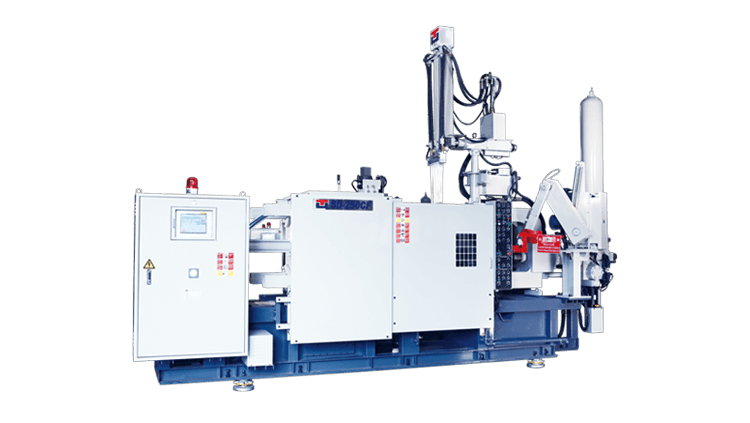

Cold Chamber Die Casting Machine 580 Ton | SD-580 CF

Advanced Aluminium Die Casting

Powerful Performance. Fast Cycle Time. Efficient & Stable. Easy To Use.

| Item | Units | SD-580 CF | ||

|---|---|---|---|---|

| Die locking force | KN | 5800 | ||

| Die platen dimensions (HxW) | mm | 1090x1180 | ||

| Space between tie bars | mm | 750x750 | ||

| Tie bar diameter | mm | 150 | ||

| Die stroke | mm | 560 | ||

| Die thickness | mm | 350~850 | ||

| Solenoid valve for core | Piece | 1/2"x2 | ||

| Hydraulic outlet | Set | 3/4"x3 | ||

| Injection force | KN | 506 | ||

| Plunger stroke | mm | 580 | ||

| Plunger-tip projection distance | mm | 250 | ||

| Injection port position | mm | -175 | ||

| Dry shot speed | M/S | 6 | 7 | 8 |

| Plunger-tip diameter | mm |

Min. 70 |

Sta. 80 |

Max. 90 |

| Maximun casting pressure | Mpa | 117.7 | 90 | 71.1 |

| Casting area | cm² |

416 624 |

544 816 |

688 1033 |

| Actual shot weight | Kg | 4.35 | 5.68 | 7.19 |

| Ejection force | KN | 259.7 | ||

| Ejection Stroke | mm | 110 | ||

| Hydraulic motor | kw | 37 | ||

| Amount of hydraulic fluid | L | 700 | ||

| Amount of cooling water for oil cooling | L/min | 80 | ||

| Amount of cooling water for die casting cooling | L/min | 50-90 | ||

| Machine weight | ton | 23 | ||

| Machine size | mm | 7590x2065x3345 | ||

| Model | 500 CF |

|---|---|

| CONTROLLER PART | |

| Color touch screen |

|

| Alarm display |

|

| Injection terms setting |

|

| Screen print |

|

| PLATEN PART | |

| Cycle time setting |

|

| Die open lubricating setting |

|

| Ejection stroke setting from screen |

|

| Movable platen adjustment |

|

| Toggles auto lubricating system |

|

| Auto tie bar puller |

|

| CORE PART | |

| Selection of core movement timer |

|

| Selection of core pressure during injection |

|

| Movable core 1 |

|

| Movable core 2 |

|

| Fixed core 3 |

|

| Pressure reducing valve for movable core 1&2 |

|

| Pressure reducing valve for fixed core 3 |

|

| INJECTION PART | |

| Motorized injection valve |

|

| Injection curve display |

|

| Die cast conditions management |

|

| Injection speed display |

|

| Injection pressure display |

|

| Injection data display |

|

| Plunger-tip projection setting |

|

| Injection vacuum movement setting |

|

| Shot sleeve clean setting |

|

| Plunger-tip lubricating setting |

|

| Injection stroke setting from screen |

|

| Magnetic non-contact sensor |

|

| Intensifying pressure adjustment |

|

| HYDRAULIC & COOLING PART | |

| Hydraulic oil temperature sensor |

|

| Hydraulic oil level sensor |

|

| Enhanced cooler | |

| Auto pressure release device |

|

| Hydraulic oil filter device |

|

| SAFETY PART | |

| Manual safety door |

|

| Full cover auto safety door |

|

| Non-operator side safety fence (without auto extractor) |

|

| Emegency stop |

|

| OTHERS | |

| Energy saving system |

|

| Digital die locking force display |

|

| Quick mould change system |

|

| Squeeze pin interface |

|

| Piston accumulator |

|

| Movable platen reinforce board |

|

| AUXILIARIES | |

| Auto ladler: Molten metal volume calculating |

|

| Auto adjustment for molten metal supply standby timer |

|

| Ladle descending position setting |

|

| Molten metal volume from screen |

|

| Auto extractor die height auto adjust |

|

| Auto sprayer die height auto adjust |

|

| Auto sprayer: Up down movement spray |

|

| Spray setting for male, female mold |

|

| Spray setting for cores |

|

| Fast auto production |

|

Standard Standard  Option Option  Not Available Not Available

|

|