Small vs Large Die Casting Machines: Which One Fits Your Factory?

Choosing the right die casting machine is a key decision for any metal parts manufacturer. Whether you're producing compact components for electronics or large structural parts for the automotive industry, the size and type of your die casting machine can significantly impact production efficiency, product quality, and overall ROI.

This guide will help you understand the key differences between small and large die casting machines, including their design, applications, and suitability for your specific production needs.

Understanding the Core Differences

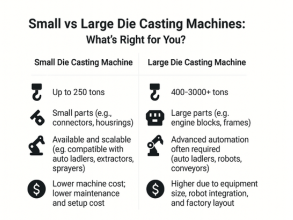

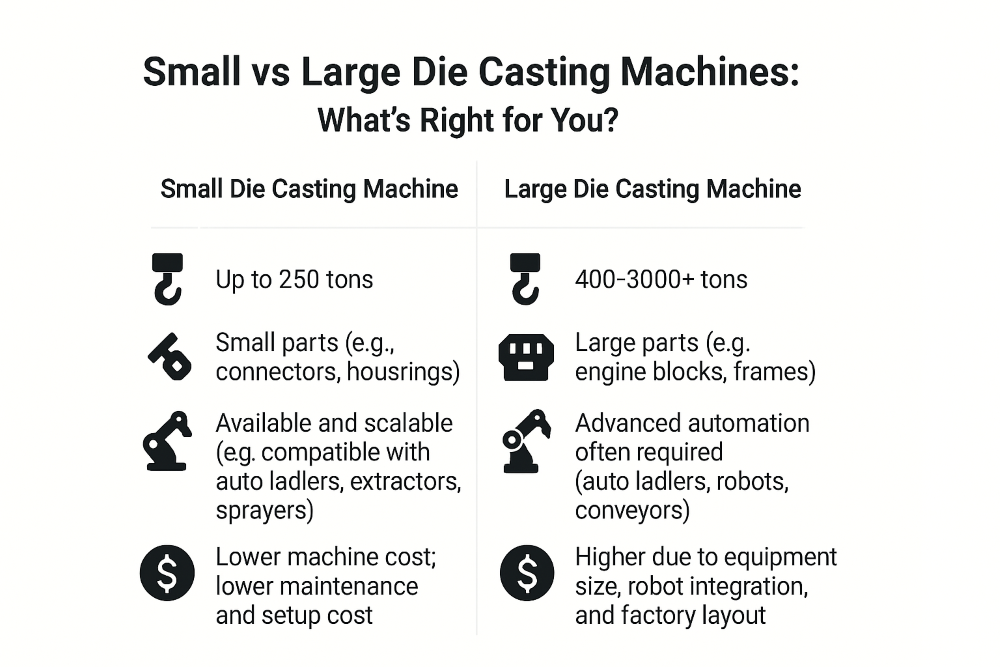

Die casting machines are generally classified based on clamping force, machine size, and part capacity. Below is a comparative overview :

| Parameter | Small Die Casting Machine | Large Die Casting Machine |

|---|---|---|

| Clamping Force | Up to 250 tons | 400–3000+ tons |

| Application | Small parts (e.g., connectors, housings) | Large parts (e.g., engine blocks, frames) |

| Machine Footprint | Compact | Large-scale |

| Cycle Time | Shorter for small parts | Longer due to part size and mold complexity |

| Material Efficiency | Lower material usage | Higher metal consumption per cycle |

| Energy Consumption | Lower | Higher |

| Automation Options | Available and scalable |

Advanced automation often required (auto ladlers, robots, conveyors) |

| Production Cost | Lower machine cost; lower maintenance and setup cost | Higher due to equipment size, robot integration, and factory layout |

Small Die Casting Machines : Compact, Efficient, and Ideal for High Precision

Small die casting machines are engineered for small-to-medium sized components and are commonly used in industries such as:

-

Consumer electronics

-

Automotive sensors and accessories

-

Medical devices

-

Lighting components

Key Advantages:

-

Space-saving design, ideal for limited factory layouts

-

Lower investment cost and easier maintenance

-

Fast cycle times, enabling high-volume production of smaller parts

-

Flexible automation options, including auto ladlers, extractors, and sprayers

TBC’s small die casting machines are optimized for precision and repeatability, making them well-suited for high-spec production environments.

Large Die Casting Machines : Built for Strength and Scale

Large die casting machines are designed for manufacturing heavy-duty, high-volume parts. Typical applications include:

-

Engine housings

-

Transmission cases

-

Motorcycle or automotive structural parts

-

Appliance chassis

Key Advantages:

-

Higher clamping force, suitable for large or thick-walled molds

-

Robust construction to handle demanding production runs

-

Capable of producing complex and structurally strong parts

-

Integrated automation systems for improved safety and throughput

Due to their size and capacity, large machines often require custom factory layouts, higher capital investment, and advanced operator training.

Which One Fits Your Production Requirements?

When deciding between small and large die casting machines, consider the following :

| Consideration | Recommended Choice |

|---|---|

| Product Size |

Small → Small machine Large → Large machine |

| Production Volume |

Low to medium → Small machine High volume → Large machine |

| Factory Space | Limited space → Small machine |

| Budget | Lower budget → Small machine |

| Component Complexity | Complex, structural parts → Large machine |

The TBC Advantage : Flexible Solutions for Every Scale

At TBC (Technology Base Corporation), we offer both small and large die casting machines tailored to your application needs. Whether you're launching a new low-volume production line or upgrading to a fully automated high-volume plant, our team can help you choose the right configuration for optimal performance.

As the first ISO9001-certified auxiliary equipment manufacturer in Taiwan, we specialize in :

-

Die Casting Machines

-

Auto Ladlers

-

Auto Extractors and Sprayers

-

Custom Metal Charging Systems, including auto pouring units and molten metal feeders

-

Release Agent Dilutors for automated mold maintenance and extended tool life

Explore our full product range:

Ready to Upgrade Your Die Casting Capabilities?

Whether you need a compact, high-speed machine or a robust system for structural metal parts, TBC provides end-to-end support, including machine customization, installation, and operator training.

Contact our die casting specialists today and let us help you identify the best machine for your factory.