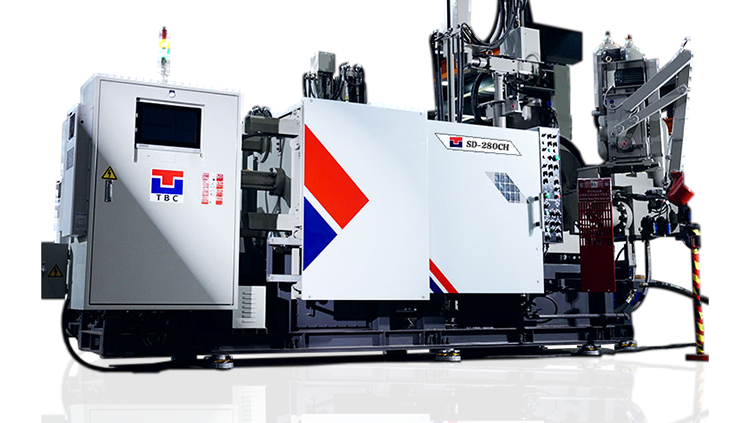

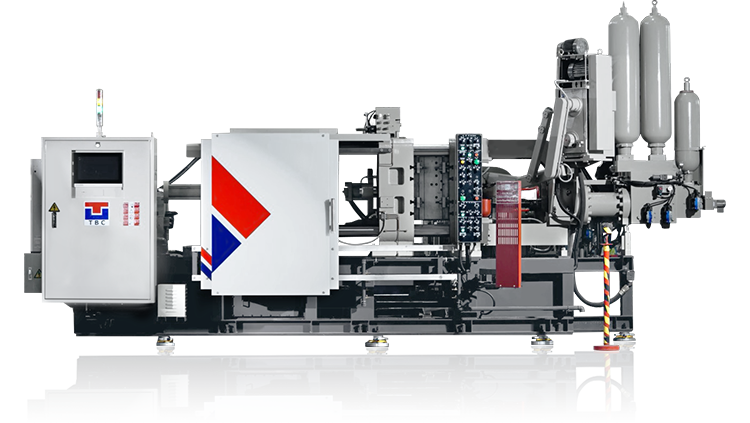

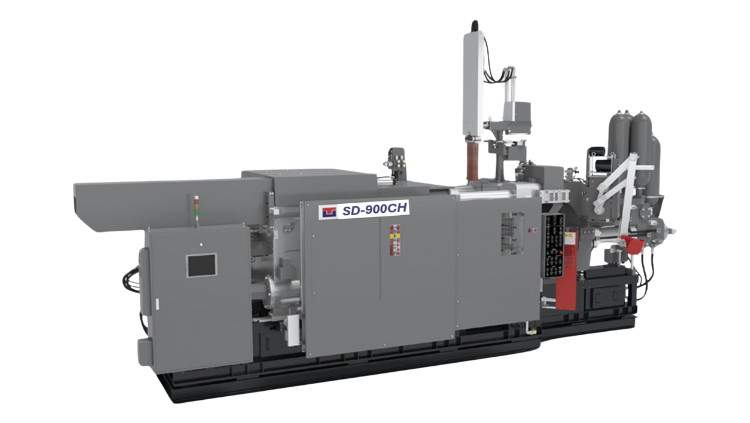

Cold Chamber Aluminum Die Casting - CH Series

High-end INTELLIGENT MODEL

CH series adopts imported energy saving system, and low speed is matched with proportional valve.

The control accuracy of multi-speed injection is better than the traditional multi-speed injection. Suitable for air-tight castings

- High speed injection 8m/ sec, high speed acceleration 80G.

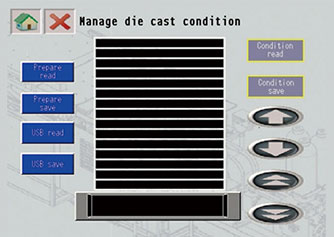

- Complete data management: Standard die clamping force, furnace temperature interface, oil temperature alarm, defective detection and other systems. 500 sets of mold parameters storage.

- With high end auxiliaries: equipped with toggle arm auto ladler and servo sprayer. Highly improving production efficiency and quality.

- Advanced Data Management: Standard for die locking force display.abandoned cast setting.detection of defective. 500 sets of parameter storage.

C Type

Standard Type

Link Type

Advanced Data Management

-

Dual Hydraulic System and Independent Intensification Accumulator:

Owing to the separate ACC for intensification part, the pressure is not influenced by high speed.

Operator can set up IP pressure independently. Suitable for 500 ton machine and above. -

Meter-in Injection System:

New hydrau-lic circuit design is capable to achieve a 80G acceleration and high speed to 8m/s.

With German proportion solenoid valve, precisely controlling multi-phase for low speed and reduce casting porosity.

Higher stability for pressure resistant products and laminar flow die casting.

Dual Hydraulic System and Independent Intensification Accumulator

Meter-in Injection System

- Vacuum system interface

- Injection parameters save up to 300 sets.

- Squeeze pin interface

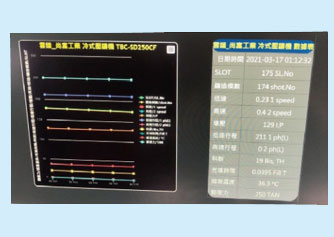

- 15 inch touch screen: Easy for operator to set parameters. The injection data function upgrade.

- Digital Clamping Force Display: Digital clamping force display is standard feature for CH models. Combined with injection data.

- Advanced electronic control function: In addition to defective detection and injection data upgrade. the mold parameter storage is extended to 1,000 sets.

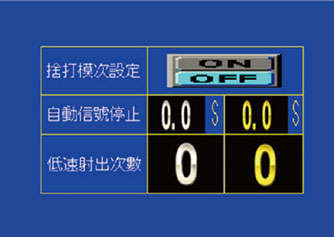

- Abandoned casting setting (warm-up model): Force the machine to operate certain shots under low-speed injection mode, according to shutdown period. Avoiding defective castings due to cold molds.

Digital Clamping Force Display

Advance Electronic Control Function

Abandoned Casting Setting

- liberación - Dispositivo de fusión

- The injection data function upgrade.

- Remoted monitoring and collection of production data.

- Simple through mobile phone or laptop.

- According to the actual measurement, the power consumption of die casting machines of 250 ton to 350 ton is reduced by about 25%.

- The power consumption of die casting machines of more than 500 ton is reduced by about 30%.

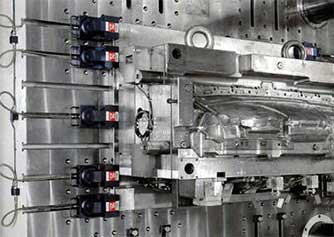

- High-end Auxiliaries: CH series is equipped with toggle-arm ladler.servo sprayer. and servo extractor. highly improving production efficiency and quality.

- Dual Hydraulic System and Independent Intensification Accumulator: Owing to the separate ACC for intesification part. the pressure is not influenced by high speed. Moreover. operator can set up IP pressure independently. Suitable for 500 ton machine and above.

- Meta-in Injection System: New hydraulic circuit design is capable to achieve a 80G acceleration and high speed to 8m/s. With German proportion solenoid value. precisely controlling multi-phase for low speed and reduce casting porosity. higher stability for pressure resistant products and laminar flow die casting.

- Advanced Data Management: Standard for die locking force display. abandoned cast setting. detection of defective. 500 sets of parameter storage.

- Remote Data Collection System: (Option):Remote monitoring and collection of production data. Simple through mobile phone or laptop.

- Energy Saving System: With German Eckerle pump and the whole new controlling system. Extend the liftspan and durability.

Remote Data Collection System

Energy Saving System

Núcleo

Sensor del nivel de aceite hidráulico

Cobertura total de la puerta de seguridad automática

Sistema de cambio rápido de moldes

Platina aerosol-lateral

Pistón tipo de acumulador

Tablero reforzado de la platina móvil

Columna extractoraautomático en el lado del operador(disponible para máquinas a partir de 580 ton)

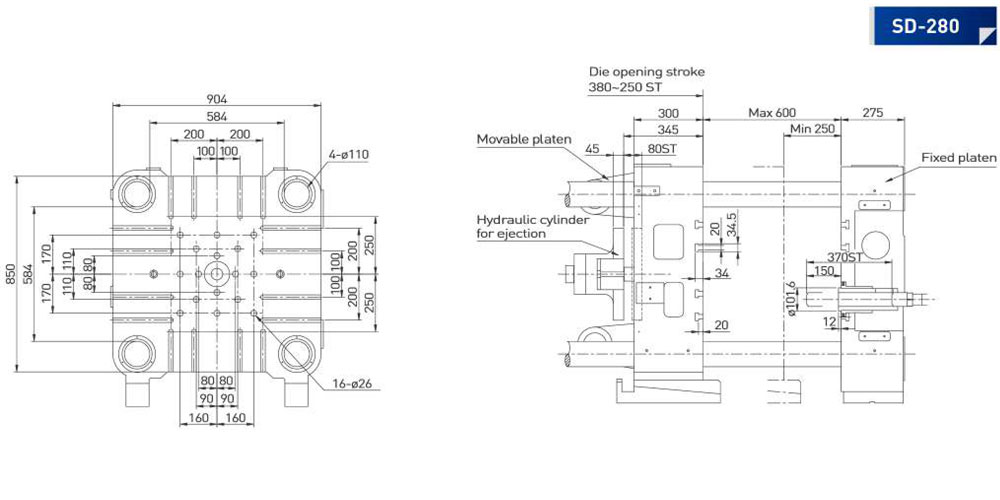

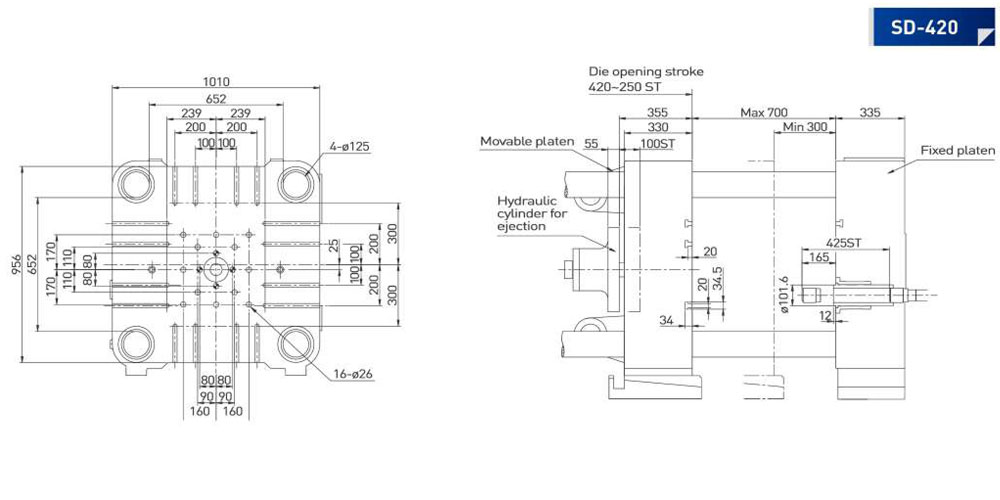

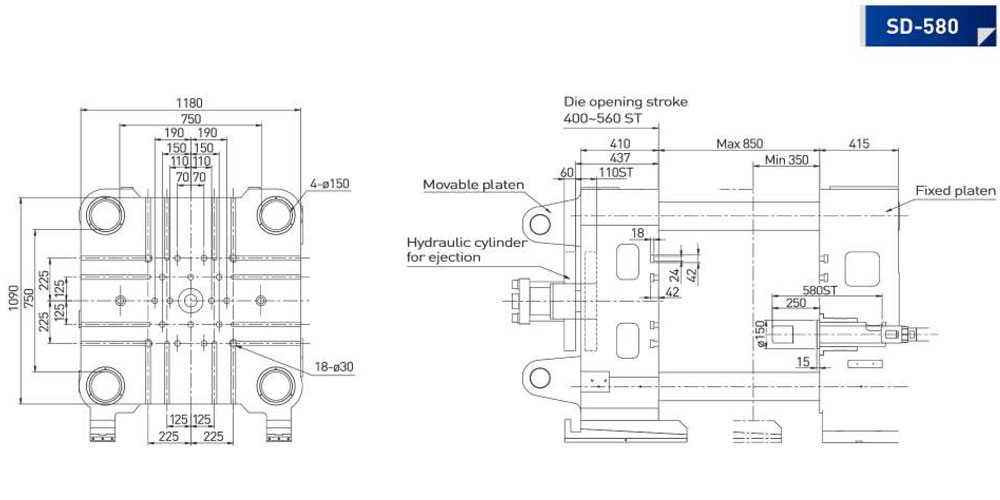

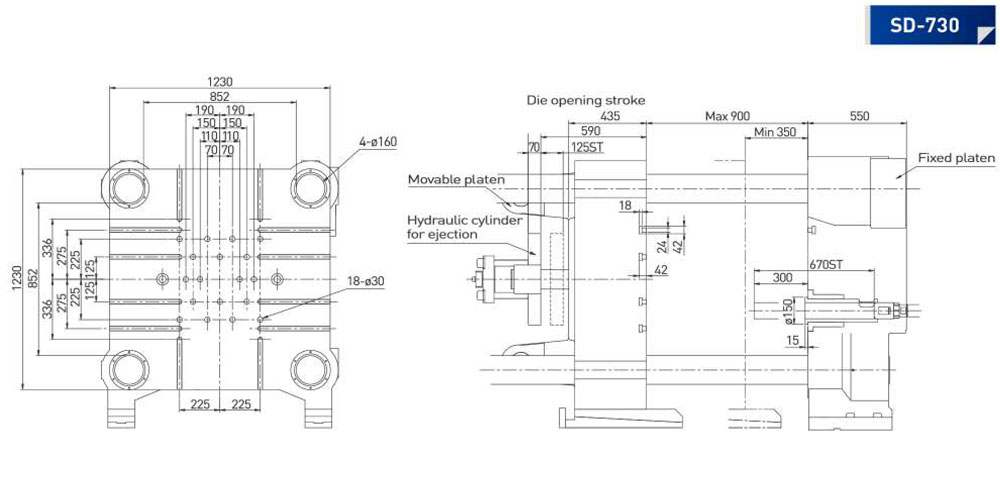

| Item | Units | SD-280 CH | SD-420 CH | SD-580 CH | SD-730 CH | SD-900 CH | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Die locking force | KN | 2800 | 4200 | 5800 | 7300 | 9000 | ||||||||||||||

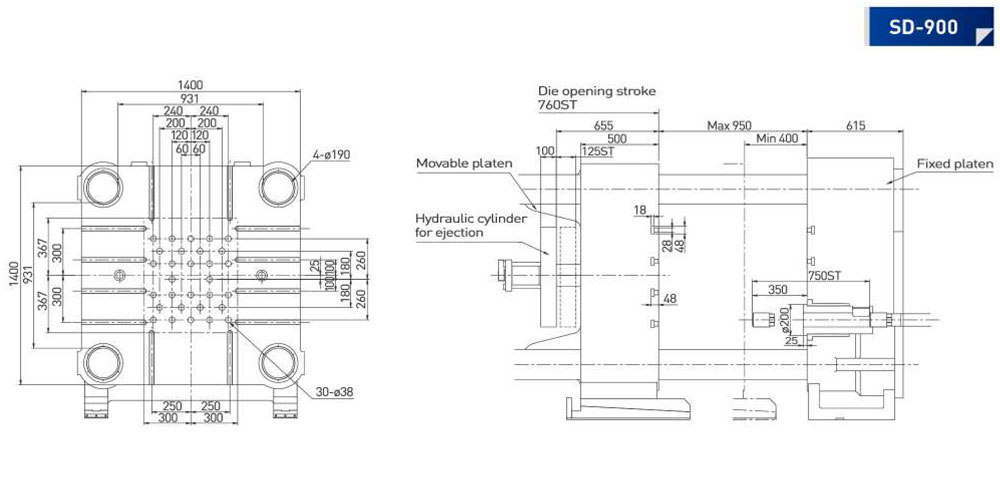

| Die platen dimensions (HxW) | mm | 850x904 | 1010x1010 | 1090x1180 | 1230x1230 | 1400x1400 | ||||||||||||||

| Space between tie bars | mm | 584x584 | 652x652 | 750x750 | 852x852 | 931x931 | ||||||||||||||

| Tie bar diameter | mm | 110 | 125 | 150 | 160 | 190 | ||||||||||||||

| Die stroke | mm | 380 | 420 | 560 | 660 | 760 | ||||||||||||||

| Die thickness | mm | 250~600 | 300~700 | 350~850 | 350~900 | 400~950 | ||||||||||||||

| Solenoid valve for core | Piece | 3/8"x1 | 3/8"x2 | 3/8"x1 | 3/8"x2 | 1/2"x2 | 1/2"x3 | 1/2"x3 | ||||||||||||

| Hydraulic outlet | Set | 1/2"x2 | 1/2"x3 | 1/2"x2 | 1/2"x3 | 3/4"x3 | 3/4"x5 | 3/4"x5 | ||||||||||||

| Injection force | KN | 265 | 354 | 506 | 550 | 653 | ||||||||||||||

| Plunger stroke | mm | 370 | 425 | 580 | 670 | 750 | ||||||||||||||

| Plunger-tip projection distance | mm | 150 | 165 | 250 | 300 | 350 | ||||||||||||||

| Injection port position | mm | -125 | -150 | -175 | -175 | -250 or -275 | ||||||||||||||

| Dry shot speed | M/S | 6 | 7 | 6 | 7 | 8 | 6 | 7 | 8 | 6 | 7 | 8 | 6 | 7 | 8 | |||||

| Plunger-tip diameter | mm |

Min. 50 |

Sta. 60 |

Max. 70 |

Min. 60 |

Sta. 70 |

Max. 80 |

Min. 70 |

Sta. 80 |

Max. 90 |

Min. 70 |

Sta. 80 |

Max. 90 |

Min. 80 |

Sta. 90 |

Max. 100 |

||||

| Maximun casting pressure | Mpa | 132.8 | 92.3 | 67.7 | 109.9 | 80.6 | 61.7 | 117.7 | 90 | 71.1 | 140.5 | 107.7 | 85.1 | 130 | 102.8 | 83.1 | ||||

| Casting area | cm² |

184 287 |

265 413 |

361 563 |

312 485 |

425 661 |

555 864 |

416 624 |

544 816 |

688 1033 |

462 582 |

604 760 |

764 962 |

653 904 |

826 1144 |

1022 1414 |

||||

| Actual shot weight | Kg | 1.40 | 2.02 | 2.75 | 2.35 | 3.20 | 4.18 | 4.35 | 5.68 | 7.19 | 5 | 6.6 | 8.3 | 7.3 | 9.2 | 11.4 | ||||

| Ejection force | KN | 123.5 | 190.1 | 259.7 | 300 | 340 | ||||||||||||||

| Ejection Stroke | mm | 80 | 100 | 110 | 125 | 125 | ||||||||||||||

| Hydraulic motor | kw | 18.5 | 22.5 | 37 | 37 | 45 | ||||||||||||||

| Amount of hydraulic fluid | L | 370 | 480 | 700 | 800 | 860 | ||||||||||||||

| Amount of cooling water for oil cooling | L/min | 25 | 25 | 80 | 80 | 150 - 180 | ||||||||||||||

| Amount of cooling water for die casting cooling | L/min | 25-50 | 25-50 | 50-90 | 50-90 | 150 | ||||||||||||||

| Machine weight | ton | 9.4 | 12.8 | 23 | 30 | 50 | ||||||||||||||

| Machine size | mm | 5613x1650x2616 | 6275x1835x2975 | 7590x2065x3345 | 8046x2335x3413 | 9990x2450x3556 | ||||||||||||||

| Modelo | 280 | 420 | 580 | 730 | 900 | |

|---|---|---|---|---|---|---|

| CH | CH | CH | CH | CH | ||

| Controlador | ||||||

| Pantalla táctil a color |

|

|

|

|

|

|

| Visualización de alarma |

|

|

|

|

|

|

| Términos de ajuste de inyección |

|

|

|

|

|

|

| Impresión de pantalla |

|

|

|

|

|

|

| Platina | ||||||

| Ajuste del tiempo de ciclo |

|

|

|

|

|

|

| Ajuste de la lubricación de la fundición abierta |

|

|

|

|

|

|

| Ajuste desde la pantalla de la dirección de expulsión |

|

|

|

|

|

|

| Ajuste de la platina móvil |

|

|

|

|

|

|

| Sistema de lubricación automática de la palanca |

|

|

|

|

|

|

| Extractor automático de la columna |

|

|

|

|

|

|

| Núcleo | ||||||

| Selección del temporizador de movimiento del núcleo |

|

|

|

|

|

|

| Selección de la presión del núcleo durante la inyección |

|

|

|

|

|

|

| Núcleo móvil 1 |

|

|

|

|

|

|

| Núcleo móvil 2 |

|

|

|

|

|

|

| Núcleo fijo 3 |

|

|

|

|

|

|

| Válvula reductora de presión del núcleomóvil 1 & 2 |

|

|

|

|

|

|

| Válvula reductora de presión del núcleo fijo 3 |

|

|

|

|

|

|

| Inyección | ||||||

| Válvula de inyección motorizada |

|

|

|

|

|

|

| Pantalla de curva de inyección |

|

|

|

|

|

|

| Administración de las condiciones de fundición |

|

|

|

|

|

|

| Visualización de la velocidad de inyección |

|

|

|

|

|

|

| Visualización de la presión de inyección |

|

|

|

|

|

|

| Visualización de los datos de inyección |

|

|

|

|

|

|

| Ajuste de proyección del pistón con punta |

|

|

|

|

|

|

| Ajuste del movimiento de inyección del vacuum |

|

|

|

|

|

|

| Ajuste de limpieza del mango de disparo |

|

|

|

|

|

|

| Ajuste de lubricación del pistóncon punta |

|

|

|

|

|

|

| Ajuste de la dirección de inyección desde la pantalla |

|

|

|

|

|

|

| Sensor sin contacto magnético |

|

|

|

|

|

|

| Intensificar el ajuste de la presión |

|

|

|

|

|

|

| Hidráulica y refrigeración | ||||||

| Sensor de la temperatura del aceite hidráulico |

|

|

|

|

|

|

| Sensor del nivel del aceite hidráulico |

|

|

|

|

|

|

| Refrigeración mejorada |

|

|

||||

| Dispositivo automático de alivio de la presión |

|

|

|

|

|

|

| Dispositivo de filtro del aceite hidráulico |

|

|

|

|

|

|

| Seguridad | ||||||

| Puerta de seguridad manual |

|

|

|

|

|

|

| Puerta cubierta automática de seguridad |

|

|

|

|

|

|

| Valla de seguridad lateral sin operador ( sin auto extractor) |

|

|

|

|

|

|

| Pausa de emergencia |

|

|

|

|

|

|

| Otros | ||||||

| Sistema de ahorro de energía |

|

|

|

|

|

|

| Visualización del bloqueo digital de fundición |

|

|

|

|

|

|

| Sistema de cambio rápido de moldes |

|

|

|

|

|

|

| Pistón acumulador |

|

|

|

|

|

|

| Tablero para reforzar la platina móvil |

|

|

|

|

|

|

| Auxiliares | ||||||

| Brazo cargador: cálculo de la cantidad de metal fundido |

|

|

|

|

|

|

| Ajuste automático para el suministro del metal fundido con temporizador de suspensión |

|

|

|

|

|

|

| Ajuste de la posición descendiente del brazo cargador |

|

|

|

|

|

|

| Visualización en pantalla de la cantidad de metal fundido |

|

|

|

|

|

|

| Ajuste automático de la altura del extractor automático |

|

|

|

|

|

|

| Ajuste automático de la altura del pulverizador automático |

|

|

|

|

|

|

| Pulverizador automático: movimiento del pulverizador de arriba hacia abajo |

|

|

|

|

|

|

| Ajuste del pulverizador para molde masculino y molde femenino |

|

|

|

|

|

|

| Ajuste del pulverizador para el núcleo |

|

|

|

|

|

|

| Producción automática rápida |

|

|

|

|

|

|

Estándar Estándar  Opcional Opcional  No disponible No disponible

|

||||||