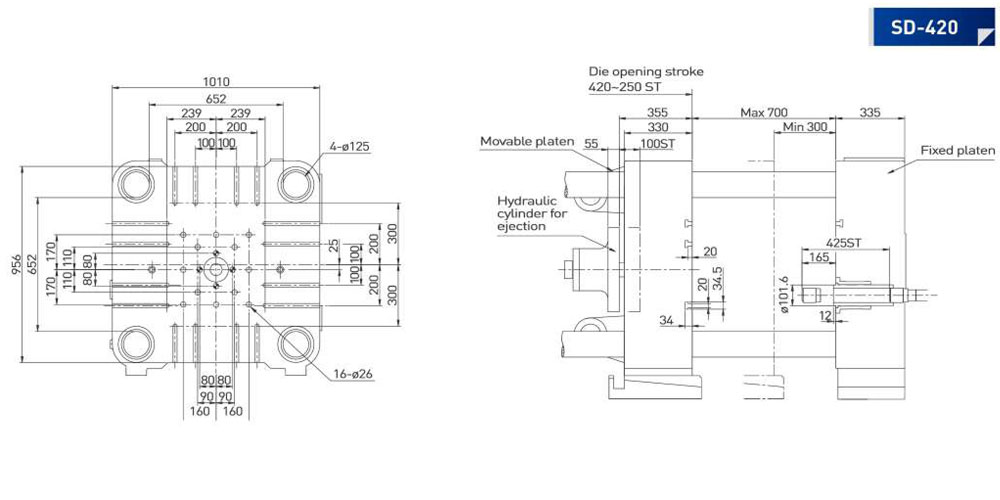

Cold Chamber Aluminum Die Casting Machine - V Series

Economic, durable and stable.

Unique Cylinder injection and exquisite circuit design, with the injection speed at 5m/ sec.

Built-in ejector for easy changeover of molds. Intuitive and ergonomics UI design for the controller.

-

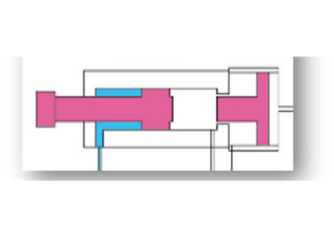

Unique Cylinder Injection:

With double cylinder injection mechanism and elaborated circuit design, injection speed can reach 5m/s. -

Auto Lubrication System:

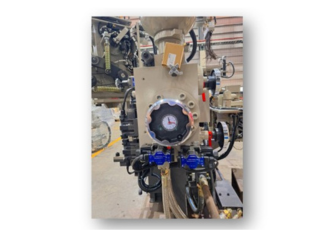

Auto lubrication system feeds the oil accurately and thoroughly, which ensures fluent actuation without being stuck. - Hand wheel adjustable injection valve with precise pressure display pointer

-

Back Pressure Relief Device

Back pressure relief device for high speed injection mode speeds up response time and increases injection velocity for quick injection stroke. - Hydraulic Oil Temperature Alarm

- 3- stage injection

- Injection Stroke Settings by LS

- Movable Platen Adjustment

- Hydraulic die thickness adjustment

- Single slide safety door

Unique Cylinder Injection

Auto Lubrication System

Back Pressure Relief Device

- Intuitive and ergonomics UI design for the controller.

- Control the die-cast parameter completely in an interface.

- Clearly display all I/O detection data.

- 100 sets of casting condition parameter data could be save

- Abnormal messages let you what problems with alarm.

-

Plunger tip lubrication device

Core 1

Core 1

| Item | Units | SD-150V | SD-280V | SD-420V | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Die Open/Close | Clamping Force | KN | 1500 | 2800 | 4200 | ||||||||||||||||||

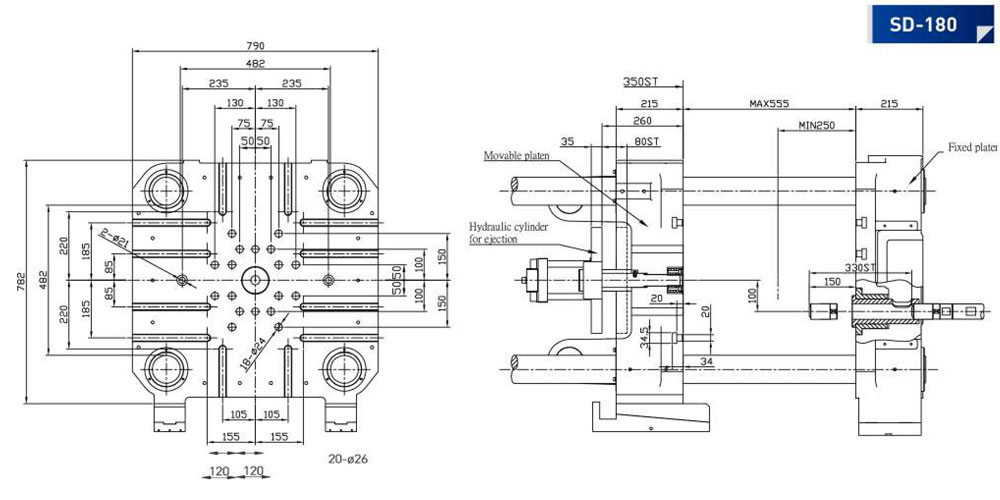

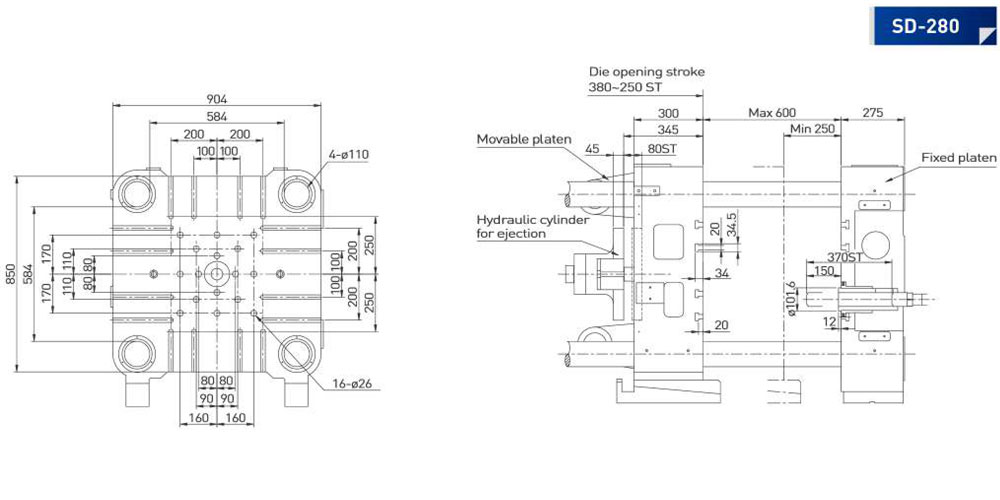

| Platen Dimensions (HxW) | MM | 730x730 | 850x904 | 956x1010 | |||||||||||||||||||

| Space between Tie Bars | MM | 460x460 | 584x584 | 652x652 | |||||||||||||||||||

| Tie Bar Diameters | MM | 90 | 110 | 125 | |||||||||||||||||||

| Die Open Stroke | MM | 350 | 380 | 420 | |||||||||||||||||||

| Mold Thickness Range | MM | 250~500 | 250~600 | 300~700 | |||||||||||||||||||

| Solenoid Valve for Core | PIECE | Option | Option | Option | |||||||||||||||||||

| Core connector | SET | Option | Option | Option | |||||||||||||||||||

| Injection | Injection force | KN | 182 | 265 | 354 | ||||||||||||||||||

| Plunger Stroke | MM | 330 | 370 | 425 | |||||||||||||||||||

| Plunger-tip Projection Distance | MM | 150 | 150 | 165 | |||||||||||||||||||

| Injection Position | MM | -100 | -125 | -150 | |||||||||||||||||||

| Dry Shot Speed | m/s | 5 | 6 | 6 | |||||||||||||||||||

| Plunger-tip Diameter | MM | Min. | Sta. | Max. | Min. | Sta. | Max. | Min. | Sta. | Max. | |||||||||||||

| 45 | 50 | 60 | 50 | 60 | 70 | 60 | 70 | 80 | |||||||||||||||

| Maximum Casting Pressure | MPA | 114.6 | 91 | 64 | 135.4 | 94.1 | 69.1 | 109.9 | 80.6 | 61.7 | |||||||||||||

| Maximum Casting Area | CM² | 128 | 159 | 229 | 180 | 260 | 354 | 312 | 425 | 555 | |||||||||||||

| 207 | 257 | 370 | 361 | 525 | 710 | 485 | 661 | 864 | |||||||||||||||

| Actual Shot Weight | KG | 0.92 | 1.16 | 1.67 | 1.40 | 2.02 | 2.75 | 2.35 | 3.20 | 4.18 | |||||||||||||

| Ejection | Ejection Force | KN | 100.9 | 123.5 | 190.1 | ||||||||||||||||||

| Ejection Stroke | MM | 80 | 80 | 100 | |||||||||||||||||||

| Others | Hydraulic Motor | KW | 15 | 18.5 | 22.5 | ||||||||||||||||||

| Amount of Hydraulic Oil | L | 360 | 370 | 480 | |||||||||||||||||||

| Amount of Water for Oil Cooling | L/MIN | 30 | 30 | 25 | |||||||||||||||||||

| Amount of Water for Mold Cooling | L/MIN | 30~60 | 30~60 | 25~50 | |||||||||||||||||||

| Machine Weight | TON | 6 | 9.4 | 12.8 | |||||||||||||||||||

| Mahine Size | MM | 4820x1520x2585 | 5613x1650x2616 | 6275x1835x2975 | |||||||||||||||||||

| Model | 150 | 280 | 420 |

|---|---|---|---|

| V | V | V | |

| CONTROLLER PART | |||

| Color touch screen |

|

|

|

| Alarm display |

|

|

|

| PLATEN PART | |||

| Toggles auto lubricating system |

|

|

|

| Tip plunger lubricating system |

|

|

|

| CORE PART | |||

| Movable core 1 |

|

|

|

| SAFETY PART | |||

| Manual safety door |

|

|

|

| Full cover safety door |

|

|

|

| Non-operator side safety fence (without auto extractor) |

|

|

|

| Emergency stop |

|

|

|

| OTHERS | |||

| Movable platen reinforce board |

|

|

|

Standard Standard  Option Option

|

|||