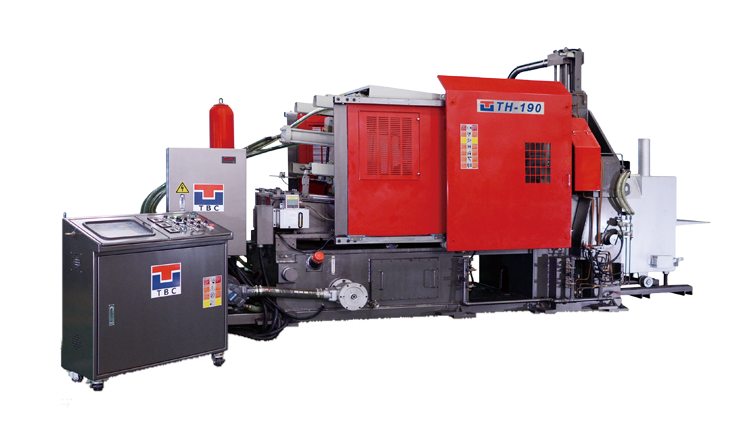

Hot Chamber Die Casting Machine

30 YEARS OF EXPERIENCE IN DIE-CASTING MACHINE

We have 30 years of R&D experience in cold-chamber die-casting machine industry best for us to produce easy-to-use, robust and stable hot-chamber die-casting machines.

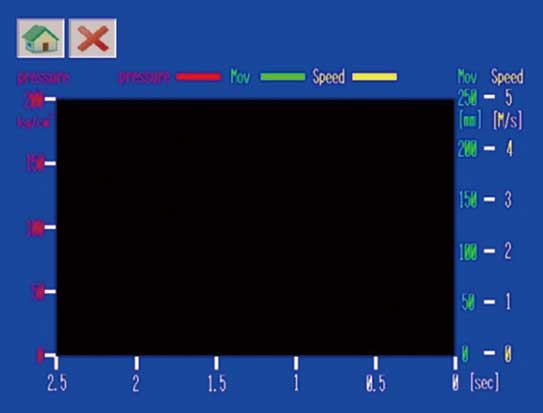

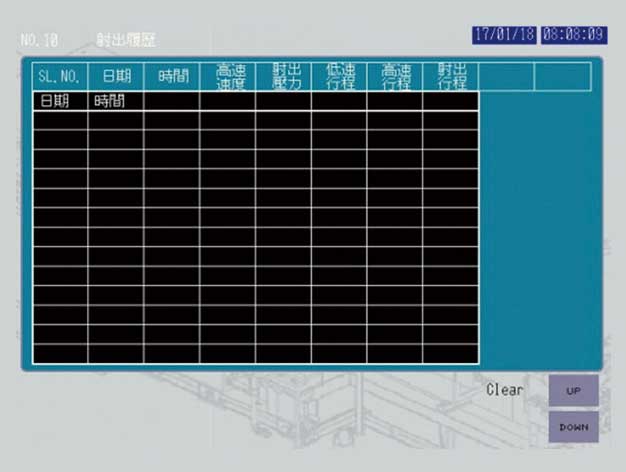

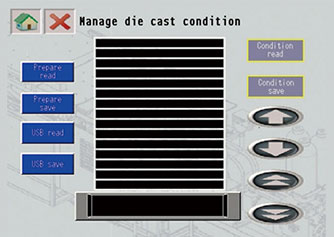

- Data Management

- -Up to 250 sets of casting conditions able to be stored

- -Enhance management efficiency

- Error message display

- -Abnormal message for troubleshooting

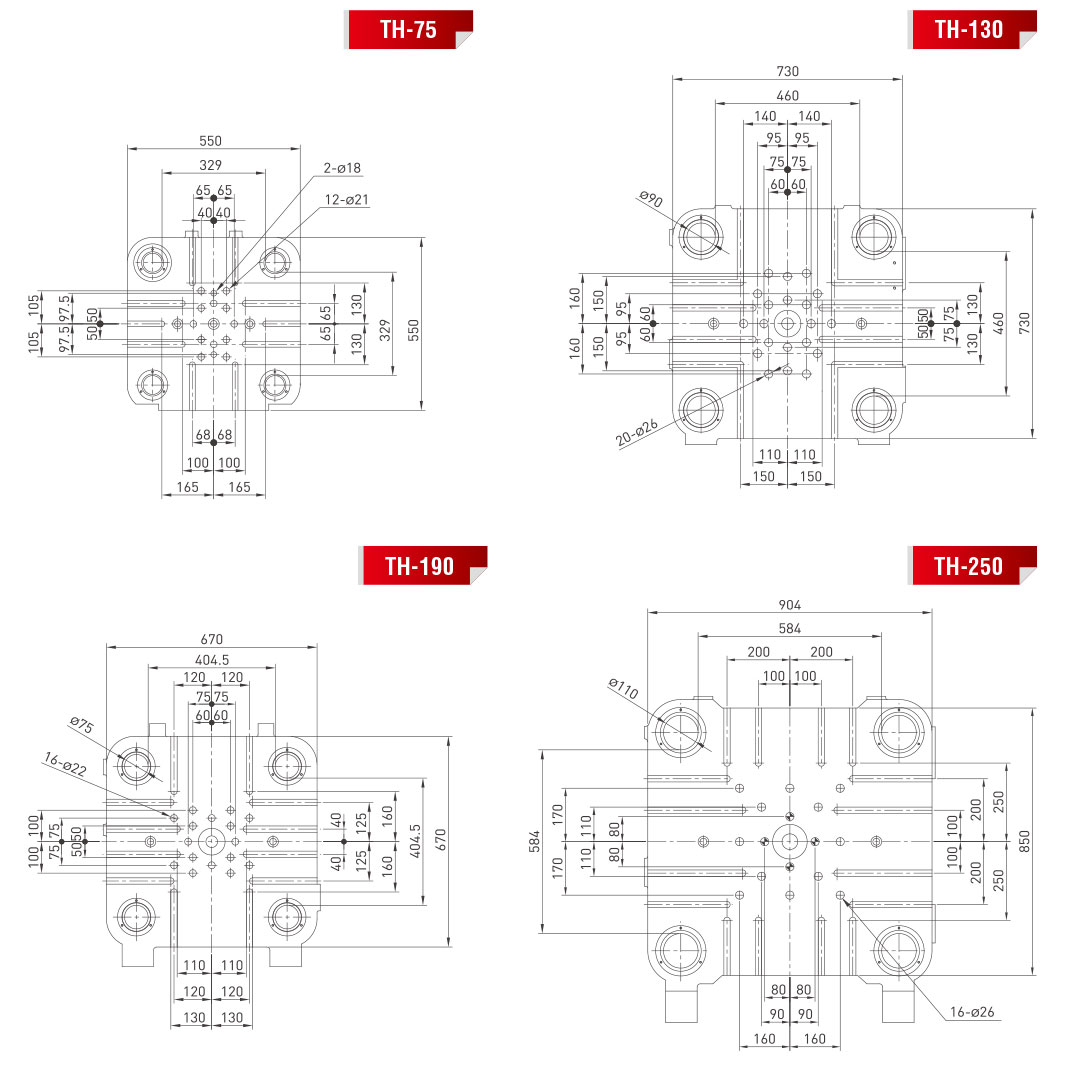

| Model | Units | TH-75 | TH-130 | TH-190 | TH-250 |

|---|---|---|---|---|---|

| Planten Part | |||||

| Die clamping force | ton | 75 | 130 | 190 | 250 |

| Tie bar diameter | mm | 60 | 75 | 90 | 110 |

| Die platen dimensions (HxV) | mm | 550 x 550 | 640 x 640 | 730 x 730 | 850 x 904 |

| Space between tie bars | mm | 329 x329 | 400 x 400 | 460 x 460 | 584 x 584 |

| Die stroke | mm | 210 | 310 | 350 | 380 |

| Die thickness | mm | 120~400 | 140~480 | 150~500 | 200~600 |

| Nozzle matching force | mm | 5.1 | 6.0 | 7.5 | 13.0 |

| Nozzle stroke | mm | 200 | 200 | 200 | 250 |

| Injection part | |||||

| Injection cylinder diameter | mm | 80 | 100 | 120 | 120 |

| Maximum injection force | ton | 5 | 7.85 | 10 | 12.5 |

| Maximum injection stroke | mm | 125 | 190 | 190 | 200 |

| Injector rod diameter (standard) | mm | 50 | 60 | 65 | 75 |

| Actual shot weight (zinc) | g | 1200 | 2500 | 3000 | 4500 |

| Furnace capacity (zinc) | mm | 0 , 60 | 0 , 80 | 0 , -100 | 0 , -150 |

| Maximum casting area | cm² | 253 | 494 | 615 | 929 |

| Casting pressure | kg/cm² | 256 | 200 | 238 | 269 |

| Ejection part | |||||

| Ejection force | ton | 5 | 6 | 7.5 | 10.5 |

| Ejection stroke | mm | 70 | 70 | 80 | 100 |

| Hydraulic part | |||||

| Operating pressure | kg/cm² | 110 | 110 | 110 | 125 |

| Accumulator (hydac) N2 (injection) | l/ea | 20 x 1 | 20 x 2 | 20 x 2 | 32 x 2 |

| Accumulator (hydac) N2 (die close) | l/ea | 10 x 1 | 20 x 1 | 32 x 1 | 50 x 2 |

| Oli tank capacity | l | 200 | 400 | 600 | 800 |

| Electrical part | |||||

| Electrical motor | kw | 11.0 | 15.0 | 18.5 | 30.0 |

| Machine size | |||||

| Machine weiht | ton | 5 | 7.5 | 10.5 | 14.7 |

| Machine size | m | 4.2x2.0x1.8 | 4.3x2.2x2.3 | 4.8x2.1x2.5 | 5.5x2.2x2.6 |