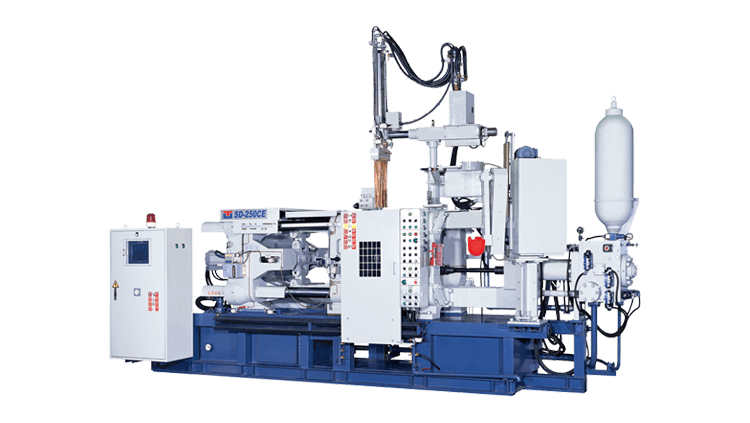

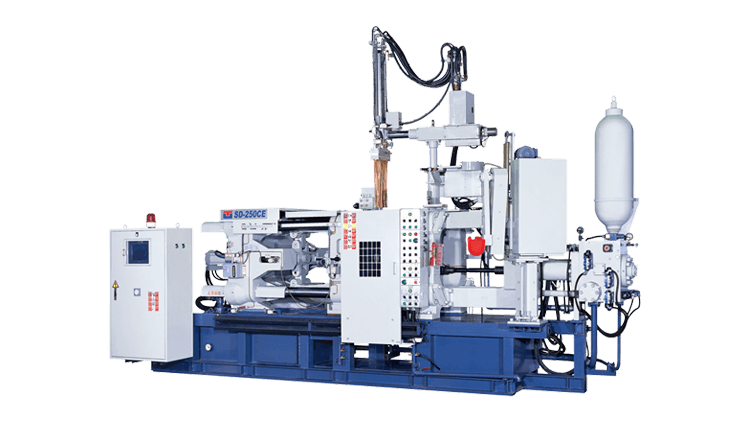

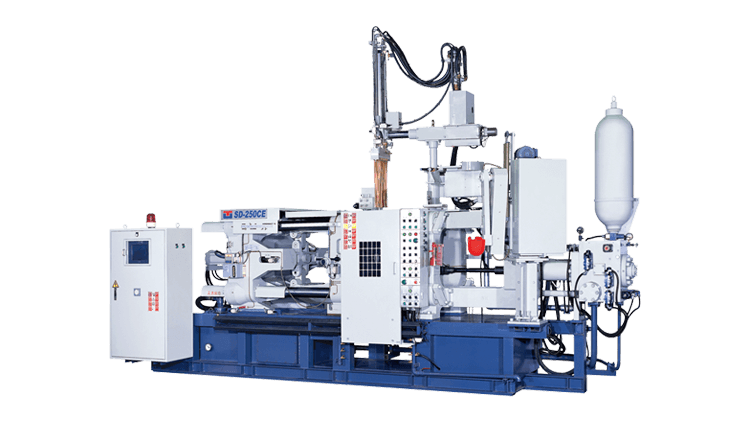

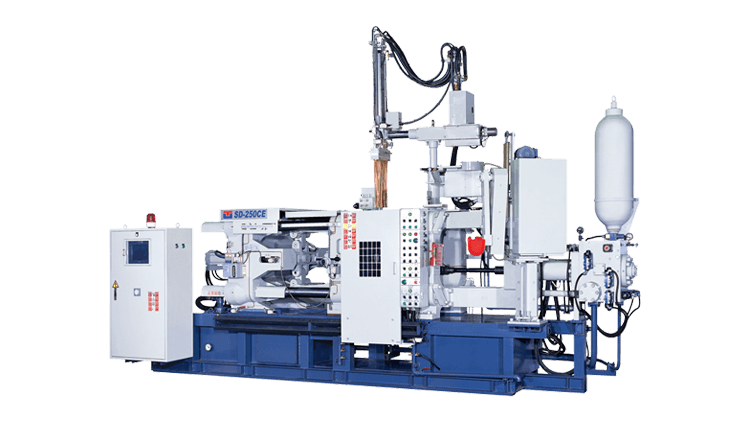

High Quality Machines Satisfy Your Die Casting Needs

Economic, Durable, Stable Performance

TBC Aluminum Alloy Cold Chamber Die Casting Machine: CE Series Models

- The best solution for cost control.

- The injection position is controlled by a non-contact sensor, using a unique circuit design.

- High-speed injection up to 6m/ sec.

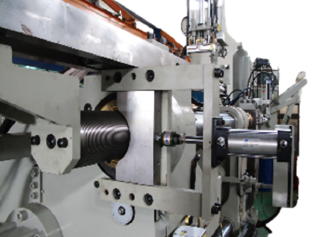

CE Injection Part Features

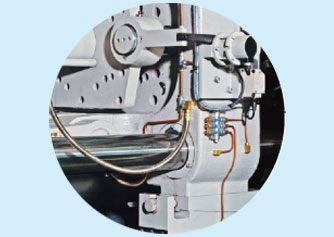

- From TBC's original design: two-cylinder injection type with specialized hydraulic circuit.

- Simple but sophisticated design, space-saving machine structure.

- Maximum dry shot speed: 5 m/s

- Injection position is monitored and controlled by specialized encoder.

- Injection position is setup and managed by HMI

- HMI: Intuitive and ergonomics UI design for controller. 100 sets of parameter storage.

- Non-contact sensor: Simple and convenient settings for injection schedule. Having a unique cylinder injection circuit design.

Human-machine Interface

Non-contact Sensor

Mechanical Structure Option:

- Speedy shaft and toggle design arrangement to enable rapid pace production.

- Easy maintenance: Full automatic lubricating system for tie-bars and toggles, lubrication can be setup by time or cycles.

- FCD cast iron material for platen structure provides excellent shock-resistance yet with stringency; machine construction is optimized by CAE.

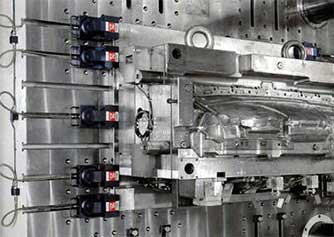

- Core movement is controlled by limit switch.

- Die height adjustment is tuned by hydraulic motor, setup is firm and stable with less break-down.

- Ejection guide bars are designed within the movable-platen for fast and easy die-replacement.

-

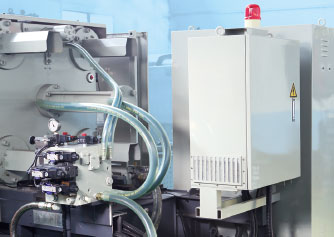

Auto Pressure Relief Device: When pumps stops, ACC pressure is automatically release to zero.

Eliminating any possible danger to maintenance engineers. - Adjustable Sliding Shoes: Easy to use and enhance the efficiency of platen adjustment.

- Injection Valve Setting: Injection valve directly con-trolled motor and encoder, setting up by HMI.

Compact Injection Design

Auto Pressure Relief Device

Adjustable Sliding Shoes

Non-contact Sensor

Injection Valve Setting

Fully Auto Lubrication System

- Color touch screen for easy operation; providing Chinese / English display.

- Digital control system to provide stable production.

- Numeric digit display for ejection adjustment and production cycle.

- Die cast parameters memory up to 100 sets.

- Error message display for easy trouble-shooting.

- Easy setup of platen movement and ejection speed.

- Core pressure and speed can be optional to control.

- Fast auto production features: collaborated with TBC original auxiliaries.

- Vacuum system interface

- Digital die locking force display

- Injection parameters save up to 300 sets.

- Squeeze pin interface

Core

Hydraulic Oil Level Sensor

Full Cover Auto Safety Door

Quick Mold Change System

Energy Saving System

Fixed Platen Side Spray

Movable Platen Reinforce Board

Auto Tie Bar Puller on Operator Side (Available for 580T machine and above)

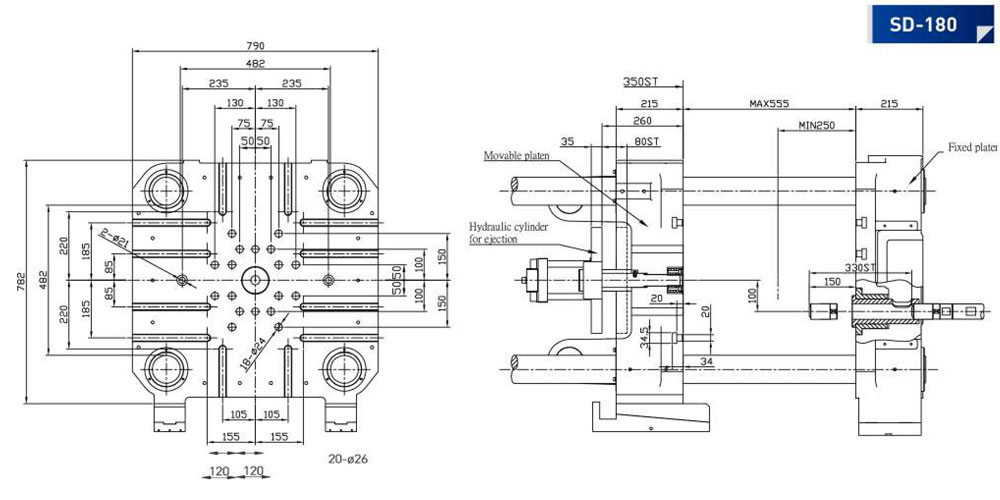

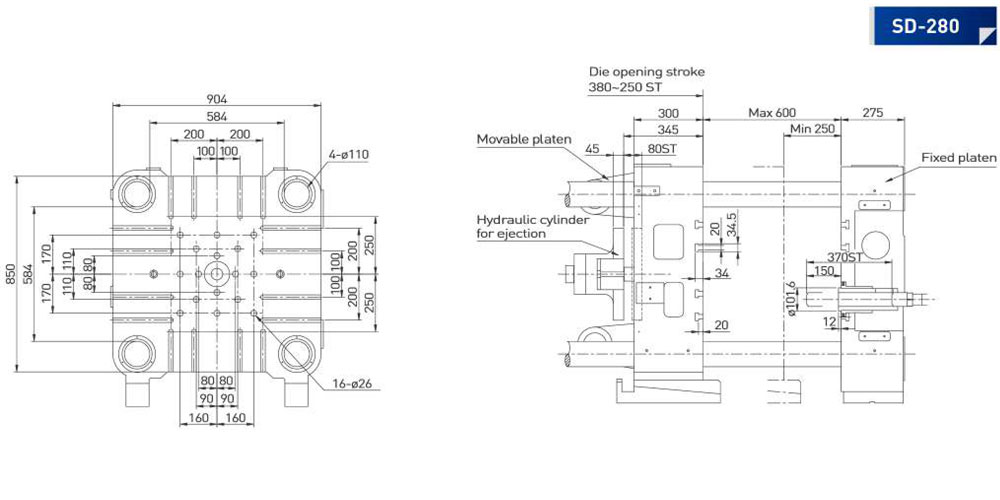

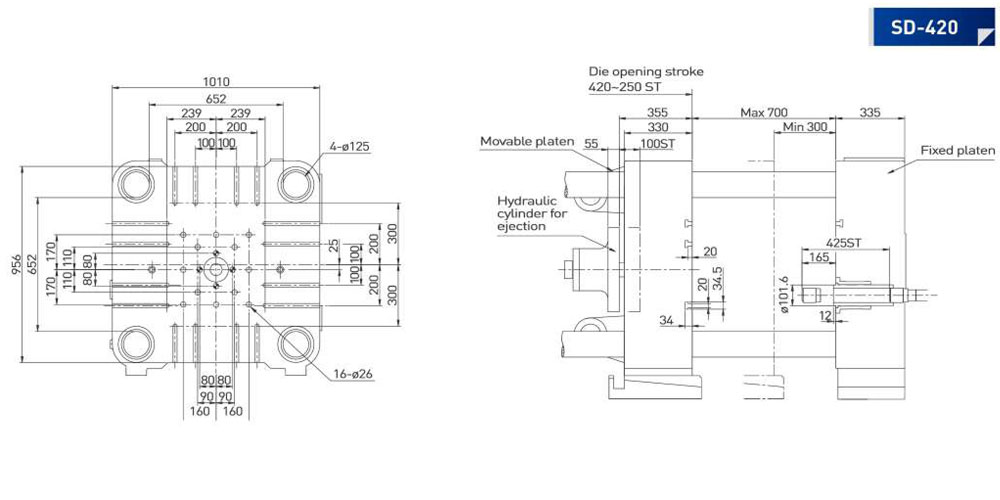

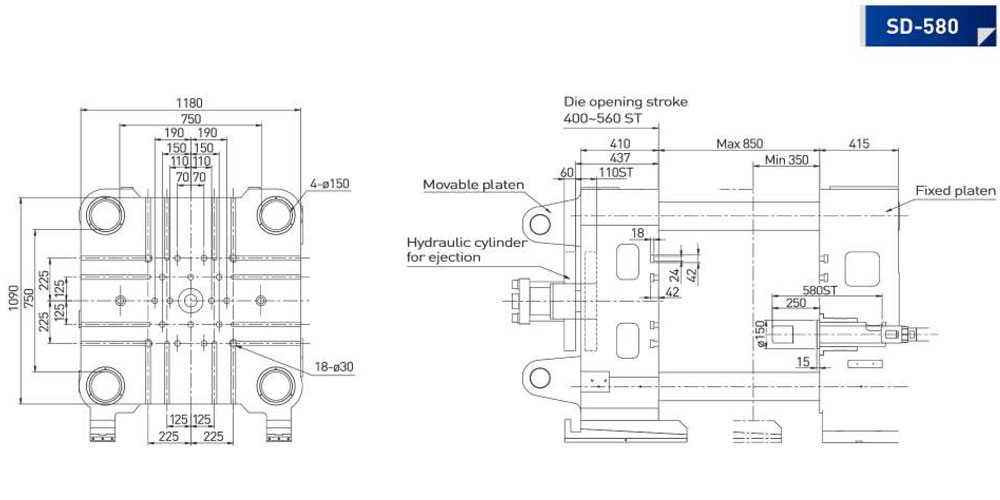

| Item | Units | SD-150 CE | SD-180 CE | SD-280 CE | SD-420 CE | SD-580 CE | SD-730 CE | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Die locking force | KN | 1500 | 1800 | 2800 | 4200 | 5800 | 7300 | |||||||||||||||

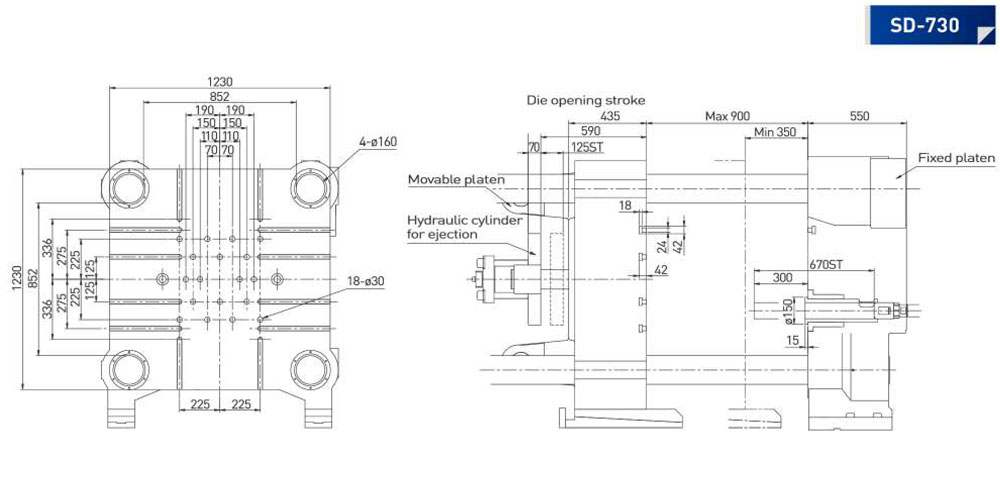

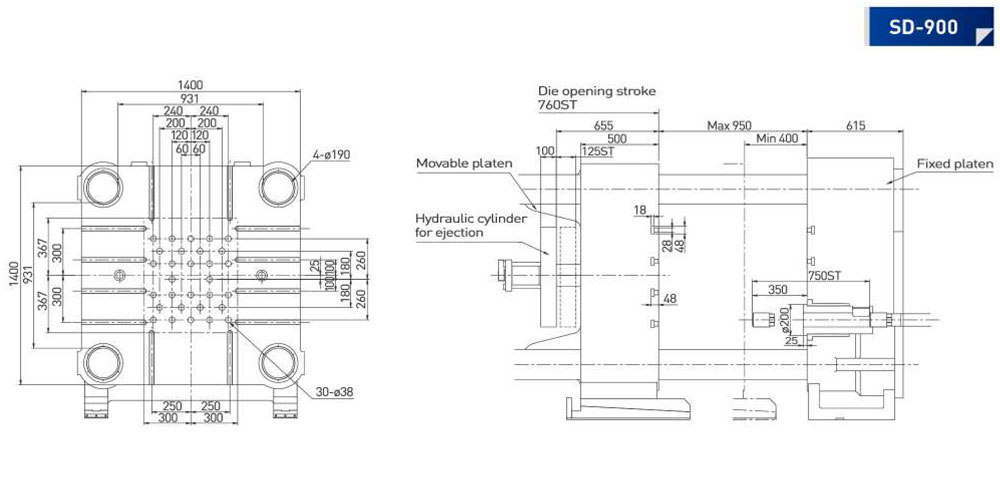

| Die platen dimensions (HxW) | mm | 730x730 | 790x790 | 850x904 | 1010x1010 | 1090x1180 | 1230x1230 | |||||||||||||||

| Space between tie bars | mm | 460x460 | 482x482 | 584x584 | 652x652 | 750x750 | 852x852 | |||||||||||||||

| Tie bar diameter | mm | 90 | 110 | 125 | 150 | 160 | ||||||||||||||||

| Die stroke | mm | 350 | 380 | 420 | 560 | 660 | ||||||||||||||||

| Die thickness | mm | 250~500 | 250~600 | 300~700 | 350~850 | 350~900 | ||||||||||||||||

| Solenoid valve for core | Piece | 3/8"x1 | 3/8"x1 | 3/8"x1 | 3/8"x2 | 3/8"x1 | 3/8"x2 | 1/2"x2 | 1/2"x3 | |||||||||||||

| Hydraulic outlet | Set | 1/2"x2 | 1/2"x2 | 1/2"x2 | 1/2"x3 | 1/2"x2 | 1/2"x3 | 3/4"x3 | 3/4"x5 | |||||||||||||

| Injection force | KN | 182 | 265 | 354 | 506 | 550 | ||||||||||||||||

| Plunger stroke | mm | 330 | 370 | 425 | 580 | 670 | ||||||||||||||||

| Plunger-tip projection distance | mm | 150 | 150 | 165 | 250 | 300 | ||||||||||||||||

| Injection port position | mm | -100 | -125 | -150 | -175 | -175 | ||||||||||||||||

| Dry shot speed | M/S | 6 | 7 | 6 | 7 | 8 | 6 | 7 | 8 | 6 | 7 | 8 | 6 | 7 | 8 | |||||||

| Plunger-tip diameter | mm |

Min. 45 |

Sta. 50 |

Max. 60 |

Min. 50 |

Sta. 60 |

Max. 70 |

Min. 60 |

Sta. 70 |

Max. 80 |

Min. 70 |

Sta. 80 |

Max. 90 |

Min. 70 |

Sta. 80 |

Max. 90 |

||||||

| Maximun casting pressure | Mpa | 110.2 | 88.9 | 61.7 | 132.8 | 92.3 | 67.7 | 109.9 | 80.6 | 61.7 | 117.7 | 90 | 71.1 | 140.5 | 107.7 | 85.1 | ||||||

| Casting area | cm² |

133 207 |

165 257 |

238 370 |

184 287 |

265 413 |

361 563 |

312 485 |

425 661 |

555 864 |

416 624 |

544 816 |

688 1033 |

462 582 |

604 760 |

764 962 |

||||||

| Actual shot weight | Kg | 0.92 | 1.16 | 1.67 | 1.40 | 2.02 | 2.75 | 2.35 | 3.20 | 4.18 | 4.35 | 5.68 | 7.19 | 5 | 6.6 | 8.3 | ||||||

| Ejection force | KN | 100.9 | 123.5 | 190.1 | 259.7 | 300 | ||||||||||||||||

| Ejection Stroke | mm | 80 | 80 | 100 | 110 | 125 | ||||||||||||||||

| Hydraulic motor | kw | 15 | 18.5 | 22.5 | 37 | 37 | ||||||||||||||||

| Amount of hydraulic fluid | L | 360 | 370 | 480 | 700 | 800 | ||||||||||||||||

| Amount of cooling water for oil cooling | L/min | 25 | 25 | 25 | 80 | 80 | ||||||||||||||||

| Amount of cooling water for die casting cooling | L/min | 25-50 | 25-50 | 25-50 | 50-90 | 50-90 | ||||||||||||||||

| Machine weight | ton | 5 | 9.4 | 12.8 | 23 | 30 | ||||||||||||||||

| Machine size | mm | 4820x1520x2585 | 5613x1650x2616 | 6275x1835x2975 | 7590x2065x3345 | 8046x2335x3413 | ||||||||||||||||

| Model | 150 | 180 | 280 | 420 |

|---|---|---|---|---|

| CE | CE | CE | CE | |

| CONTROLLER PART | ||||

| Color touch screen |

|

|

|

|

| Alarm display |

|

|

|

|

| Injection terms setting |

|

|

|

|

| Screen print |

|

|

|

|

| PLATEN PART | ||||

| Cycle time setting |

|

|

|

|

| Die open lubricating setting |

|

|

|

|

| Ejection stroke setting from screen |

|

|

|

|

| Movable platen adjustment |

|

|

|

|

| Toggles auto lubricating system |

|

|

|

|

| Auto tie bar puller |

|

|

|

|

| CORE PART | ||||

| Selection of core movement timer |

|

|

|

|

| Selection of core pressure during injection |

|

|

|

|

| Movable core 1 |

|

|

|

|

| Movable core 2 |

|

|

|

|

| Fixed core 3 |

|

|

|

|

| Pressure reducing valve for movable core 1&2 |

|

|

|

|

| Pressure reducing valve for fixed core 3 |

|

|

|

|

| INJECTION PART | ||||

| Motorized injection valve |

|

|

|

|

| Injection curve display |

|

|

|

|

| Die cast conditions management |

|

|

|

|

| Injection speed display |

|

|

|

|

| Injection pressure display |

|

|

|

|

| Injection data display |

|

|

|

|

| Plunger-tip projection setting |

|

|

|

|

| Injection vacuum movement setting |

|

|

|

|

| Shot sleeve clean setting |

|

|

|

|

| Plunger-tip lubricating setting |

|

|

|

|

| Injection stroke setting from screen |

|

|

|

|

| Magnetic non-contact sensor |

|

|

|

|

| Intensifying pressure adjustment |

|

|

|

|

| HYDRAULIC & COOLING PART | ||||

| Hydraulic oil temperature sensor |

|

|

|

|

| Hydraulic oil level sensor |

|

|

|

|

| Enhanced cooler |

|

|

|

|

| Auto pressure release device |

|

|

|

|

| Hydraulic oil filter device |

|

|

|

|

| SAFETY PART | ||||

| Manual safety door |

|

|

|

|

| Full cover auto safety door |

|

|

|

|

| Non-operator side safety fence (without auto extractor) |

|

|

|

|

| Emegency stop |

|

|

|

|

| OTHERS | ||||

| Energy saving system |

|

|

|

|

| Digital die locking force display |

|

|

|

|

| Quick mould change system |

|

|

|

|

| Squeeze pin interface |

|

|

|

|

| Piston accumulator |

|

|

|

|

| Movable platen reinforce board |

|

|

|

|

| AUXILIARIES | ||||

| Auto ladler: Molten metal volume calculating |

|

|

|

|

| Auto adjustment for molten metal supply standby timer |

|

|

|

|

| Ladle descending position setting |

|

|

|

|

| Molten metal volume from screen |

|

|

|

|

| Auto extractor die height auto adjust |

|

|

|

|

| Auto sprayer die height auto adjust |

|

|

|

|

| Auto sprayer: Up down movement spray |

|

|

|

|

| Spray setting for male, female mold |

|

|

|

|

| Spray setting for cores |

|

|

|

|

| Fast auto production |

|

|

|

|

Standard Standard  Option Option  Not Available Not Available

|

||||